Dover Conveyor, Inc. products

Dover Conveyor - Bucket Elevators

A typical bucket elevator consists of a series of buckets mounted on a chain or conveyor belt moving materials straight up at 90 degrees. This traditional method of conveying is one of the most economical, efficient, and dependable means of elevating loose bulk materials. The initial cost is low; maintenance is minimal; and a long life can be expected.

Dover - Drag Conveyors

Dover`s Drag Conveyors utilize a wear-resistant coal mining chain with reinforced drag cleats. This heavy duty conveying configuration is custom designed and fabricated to meet the demands of your specific application. With over 160 years combined experience, our engineering team has yet to see a “standard” application.

Dover - Hinged Steel Belt Conveyor

Widths up to 96", pitches up to 18" Suited for scrap metal, paper, and other severe duty applications, the steel belt conveyor is known for its high impact capability and forgiving nature. "ZEE" configurations eliminate the need for two or more conveyors. Layouts requiring straight, level, inclined, or any other configuration are possible with this style of conveyor.

Dover - Pli-O-Wall Conveyors

Pli-O-Wall Conveyors are an exciting category of conveyors because of their many impressive capabilities. The Pli-O-wall conveyor can transport materials/substances at high degrees of inclines, (up to 90 degrees), in “ZEE” configurations that eliminate the need for two or more conveyors and drives. These high-angle configurations are preferable when floor space is at a premium, or there are tight centerlines between specified destinations. The material/substance stays contained and in place with bucket-like pockets created by flexible sidewalls and risers. These are corrugated, thus enabling them to bend around pulleys and rollers.

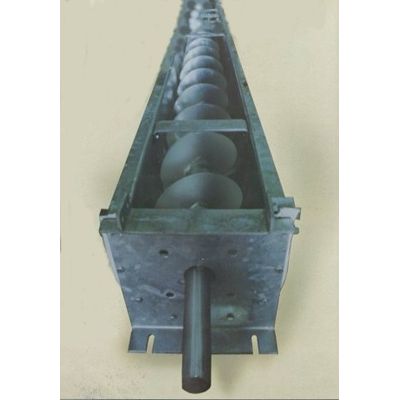

Dover - Screw Conveyors & Feeders

Food, drug, agricultural, general and mining industries use this type of conveyor when a fully contained, metered effect is required to handle consistent materials such as grain, sludge, powders, dry chemicals, etc. Screw Conveyors are an effective way to move wet or dry bulk materials along a totally enclosed incline or horizontal length. This concept is effectively used when a totally enclosed design fits the nature of the material, by preventing spillage, spewing dust, etc.

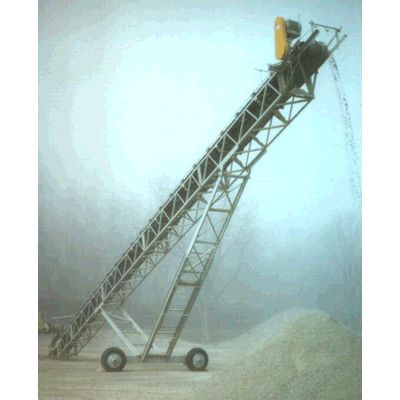

Dover - Stacking Conveyors

A Dover Specialty! Radial Stacking Conveyors are trough belt conveyors with the ability to turn from a point on an arc and build storage piles. Dover manufactures both underslung and mast styles. We use CAD computer aided design, modular construction, and jig-built trusses to ensure a square and true design. Every radial stacker is engineered for heavy-duty performance and reliability. Dover’s designs run from 30’ through 200’ in length and from 24” through 84” belt widths.

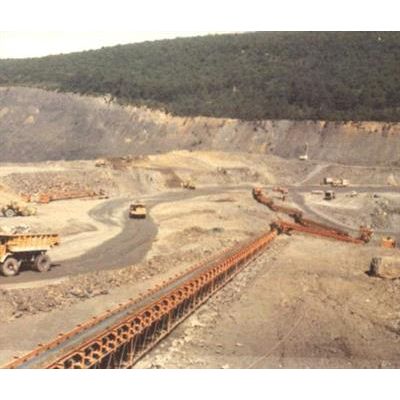

Dover - Overland Systems

Dover Overland Systems: Dover can produce Truss, Channel Frame, and Wire Rope Conveyors through miles in length. Upon request, Dover can produce quality, jig-built pipe trusses for your conveyor system. Pipe trusses are stronger, self cleaning, and reduce the number of supports needed. They consist of four pipe cords connected by diagonal pipes to form a laced-frame truss, squared and welded. The resulting truss provides a rigid member which is stronger than a conventional angle iron truss of the same weight. There are no grooves or crevices to lodge loose material or harmful moisture. This increases its useful life and reduces maintenance.

Dover - Tripping Conveyors

Tripping Conveyors discharge materials along the length of a belt. Both aggregates and large bulky materials,(such as aluminum bales), can be off-loaded with trippers.

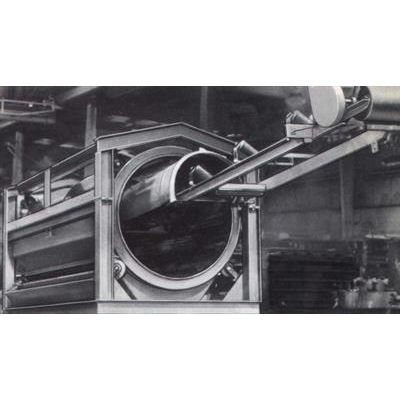

Dover - Trommels & Finger Screens

Dover’s Trommel Screens are another example of Dover’s custom engineering and fabricating capabilities. Trommels can be supplied at any size or style for classifying materials. In addition to its use for screening and sizing, the Trommel Screen has a controlled speed which provides a scrubbing action. This improves separation, minimizes need for service, and provides a self-cleaning system that is the easiest to maintain. The Trommel Screen can be used to loosen and mix compacted materials

Dover - Troughing Conveyors

Trough Belt Conveyors: One of the most “forgiving” designs because of the open frame and trough effect of the rubber belt fully containing the load of material. Trough belt conveyors are the most widely used and efficient means of moving bulk materials. Rubber belt conveyors are designed for handling high tonnages and are generally low in maintenance.