Duke’s Metal Industries products

Duke Metal - Industrial Wedge Wire

Wedge wire are produced using cross-sectional dimensions to minimize and eliminate costs and provide you with continuous form. They are available in hundreds of alloys and can be produced to specific physical properties based on your requirements. Advantages of these wires include continuous coils, close dimensional tolerances, no burr, intricate specialty and custom edges, and in-process gauge and measurement. The most popular alloys include Stainless Steel, Nickel, Cobalt, Titanium, Copper, Carbon Steel, Aluminum, Nitinol, and Special Metals. Since these can be custom-created to meet your project requirements, they are a great solution for your needs.

Duke Metal - Pipe Mesh Rolls

Pipe mesh rolls come in variable widths and lengths with Aluminum and Carbon Steel options. Commonly used to reinforce concrete pipes, pipe mesh ensures strength and durability and meets the structural requirements for compliance. As with all of our products, you can ensure that you get the versatile, practical solutions to meet your project requirements.

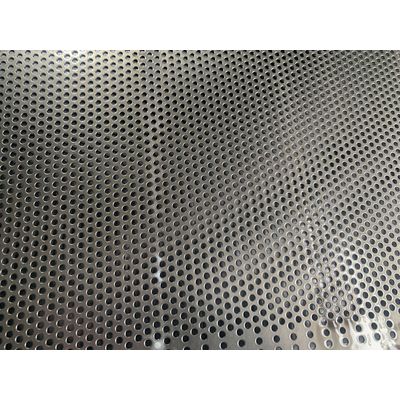

Duke Metal - Perforated Metal

Check out our vast selection of perforated metal with various sizes, gauges, and hole types that make these products perfect for any project. Perforated Metal brings strength and style to enclosures, partitions, sign panels, guards, screens, and other structures in high-end and industrial settings. We carry our fantastic product line because it provides ventilation, versatility, and a high strength-to-weight ratio. It’s also a valuable option when you need filtration of sound, liquid, light, etc.

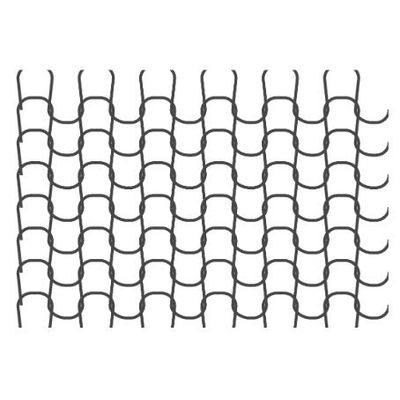

Duke Metal - Knitted Mesh

Knitted Mesh is a low-cost product that offers excellent product efficiency over a wide range of conditions. Made from individual wires interlaced together, the loops of this mesh are strategically woven to move and stretch without coming undone. Just like a sweater, these properties make knitted mesh very flexible. The mesh will return to and maintain its original shape at all times unless it is stressed beyond its designated yield point.

Duke Metal - Reverse Plain Dutch Weave Mesh

Manufactured as a Reverse Plain Dutch Weave or RPDW, this wire mesh comes in a twill pattern that reduces the deformation of the warp wire. This mesh is particularly strong with a high flow rate, adding stability and durability to your project. It is perfect for high-pressure filtration, including continuous filter screens and sand screen applications. Dutch weaves cross two wires under and two over, allowing heaving wires and higher mesh counts. In these applications, the weft wires are drawn up so tightly that there is always a weft wire above and below the warp wires. this creates a weave that completely covers the warp wires, adding superior strength.

Duke Metal - Reversed Dutch Twilled Weave Mesh

RDTWs are reversed dutch twilled weave meshes developed for increased strength. As a world-class leader in technical metal weaving of stainless-steel architectural mesh systems, GKD Metal Fabrics’ state-of-the-art weave technology enables an even pore size and stability, high flow rates, and narrow tolerance fields in the pore dimensions. These metal products enhance the overall aesthetics, function, and efficiency of every project for which they’re used. In many cases, the RDTW weave is referred to as KPZ Microdur weave or KPZ.