- Home

- Companies

- Dumag GmbH

- Products

Dumag GmbH products

Systems

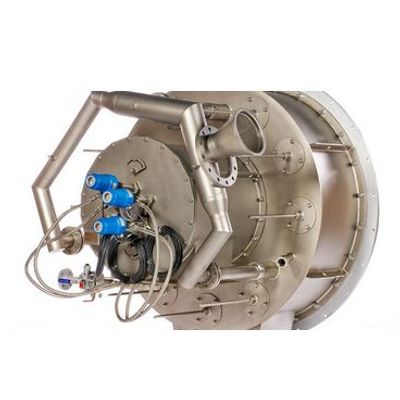

Dumag - Thermal Oxidizer

The interaction between the burner and the combustion chamber geometry plays an important role in complying with all the relevant regulations and achieving a process that is optimized in terms of energy.

Dumag - Regenerative Thermal Oxidizer

- The main argument for selecting the regenerative over the recuperative technology is the outstanding heat recovery efficiency which is achieved thanks to the extraordinary surface area of the heat storage media. It can be assumed that regenerative systems easily reach a thermal efficiency of 95% or even higher. This means that heat recovery is nearly twice as high as it would be when a recuperative tube-shell heat exchanger is used. Apart from the significant savings in support fuels for operation, the system shows a relatively low pressure drop resulting in reasonable overall OPEX figures. Shut-down inspections are usually required once per year. There are some specific petrochemical applications, however, for which uninterrupted operation for up to 4 years has been achieved. The robust and proven design by DUMAG ensures trouble-free operation and long service life – even under harsh conditions.

Products & Components - Industrial Burners

Dumag - Model IBX - Industrial Low NOx Burner

Thanks to the special features of the DUMAG® IBX model, the burner system can significantly reduce thermal (temperature related) and fuel attributable (fuel bound nitrogen) NOx formation. A double or triple staged burner air supply, utilizing precisely positioned and directed lances, effectively reduces NOx combustion emissions.

Liquid Fuel Atomising Nozzles

Dumag - Ultrasonic Fuel Atomising Nozzles

The functional principle of atomization of the DUMAG® Ultrasonic Nozzle is based on the principle of the Hartmann generator. In contrast to conventional atomizer nozzles, compressed air or steam and medium, such as liquid waste materials, clash briefly outside the nozzle. This enables the throughput of liquid media at low inlet pressure. The high-frequency vibrations generated by the geometry of the nozzle result in a fine dispersion of the medium and, subsequently, in an optimum combustion process.