- Home

- Companies

- Dustcheck Limited

- Products

Dustcheck Limited products

Dust Collectors

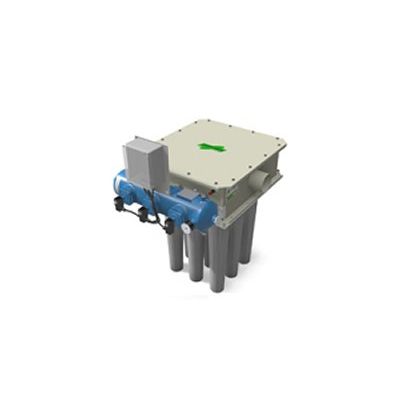

Model D 135 - Industrial Dust Collectors

Industrial Dust Collectors are ideal for applications where a ductwork system draws product back to a centralised filter as they extract air borne contaminants to produce air quality of the highest standard. The Dustcheck range of Industrial Dust Collectors has evolved over 30 years and is installed in over 1000 projects ranging from handling individual points, to large multiple extraction systems. The dust collector systems automatically clean collected product, disposing it in a controlled way.

Filters Products

Model D 24 - Vessel Venting Filters

Filters for mounting on vessels, which are fed with dry powders causing air displacement. Vessel Venting Filters allow the displaced air to flow through the filter, trapping particulate to allow clean air to be vented, the filtered particulate is returned to the vessel via an automatic reverse jet cleaning system, thus ensuring a self maintained unit allowing continuous venting. The Vessel Venting Filter is a compact unit designed to vent small air volumes, efficiently replacing the old ‘floppy sock’.

Model D 171, 163 & D 209 - Silo Venting Filter

Silo Venting Filters are specifically designed to vent silos fed with powdered products primarily from road tankers. Capable of filtering the product from the air during the conveying period and the air surge at the end of the cycle. The filter is self maintaining returning product back into the silo via an automatic reverse pulse compressed air cleaning system. The filter utilises ‘conical’ filter technology complying with environmental emission standards, has a rugged weatherproof construction and designed for safe simple maintenance.

Model D - Venting Filter

Venting filters return product back into the system, reducing waste and cutting costs. Dustcheck’s range are self-maintaining and available in rectangular or circular construction for cleanside and dirtyside removal, horizontal and vertical mounting ensures the most flexible economic technical solution.

Model D 116 - Protection Filters

“Inlet” and “Inline” protection filters clean air to the highest levels before, during or after the production process. Dustcheck’s protection filters have applications for any process where high quality air is required, but particularly within the Food and Pharmaceutical industries. These can be air inlet filters usually F3-F9 efficiency or inline system filters F9 to H14 efficiency for either maintaining high air quality to enable recirculation or to protect equipment.

Model D195, D76 - Vacuum Clean-up Systems

Dustcheck’s wide range of Industrial Vacuum systems create a cleaner safer workplace and offer the advantage of multiple user operation. They collect all waste in one central location for fast and efficient disposal. These can be applied to general cleaning systems where a range of cleaning attachments are available to suit the customer’s needs or heavy duty material transfer. Whether a general factory clean up system, a bulk spillage transfer system or a high vacuum dust control system, all are tailored to meet individual application requirements.

Oil Mist Filters

Dustcheck market MAHLE oil mist filters which collect atomised fluids and re-circulate environmentally safe air. Oil mist can cause a serious health hazard and create a dangerous environment if left uncollected by way of slippery surfaces or a grease covered plant and equipment. MAHLE oil mist filters remove oil/lubricant mist generated through your production processes, returning oil to the machine and clean air to the workplace.

Special Filter

Dustcheck understand your industry and our experienced team is continually working to develop new products. Dustcheck’s experience offers special designs for bespoke applications or products designed and badged under your name.

Turnkey Systems

Dustcheck offers professional Turnkey System installations, this can include a complete consultation, design, manufacture, installation, commission and after sales service. Our experienced team offer design facilities for hoods to give correct / efficient dust capture, duct design, controls, installation with appropriate risk assessment and method statement. Final commissioning with documentation to enable ongoing LEV testing to comply with Health and Safety legal obligations. See our ‘Service and Spares’ section.

Cleaning Systems

Dustcheck produce not only the best filter for your application but combine this with the most suitable cleaning system to provide optimum performance. The filter has to function efficiently to maintain even air flow, the filter media, the cleaning system and cabinet design are all important factors.