E & I Corporation products

E&I Corp - Arc Screens

The Arc Screen is a front cleaned mechanical bar screen specifically developed for small plants. The screen has a spring loaded rake that rides over compacted debris, in lieu of jamming. This screen is for channels 12-24” wide to a maximum of 36” deep. The unit is driven by a cost effective shaft mounted gear motor, controlled by an electronic overload device. As all E & I Corporation Screens, the Arc Screen has no underwater parts subject to maintenance. This screen is very reliable and cost effective for low flow conditions and small plants.

E&I Corp - Catenary Bar Screens

The E&I Catenary Bar Screen is an extra heavy duty front cleaned, front return mechanical bar screen. The screen utilizes two (2) strands of steel chain that is heavier and has superior strength than any other screen chain. Connected between these chains are counter weighted rakes that remove debris trapped on the bar rack. Since the chain links lock onto themselves to form a rigid "catenary curve", the lower sprocket is eliminated – facilitating easier inspection & maintenance; and is less susceptible to blockages, damage and corrosion than chain driven units. The result is a much longer operating life, less maintenance shutdowns and lower maintenance cost.

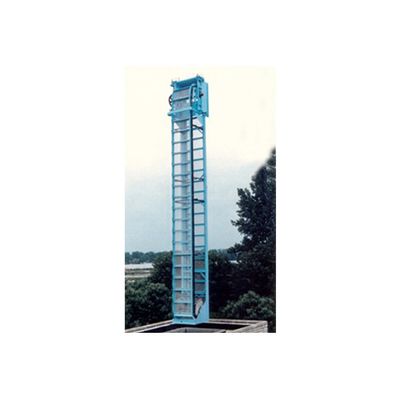

E&I Corp - Catenary Trash Rake

The E&I Corp Catenary Trash Rake was born in the stormwater industry. For years, the Trash Rake has maintained its reputation as the answer to screening large volumes of water containing debris such as tree branches, logs, automobile tires or any type of solid material that can be carried into the screening channel. Typically the Trash Rakes are the first line of defense in an intake structure - designed to accommodate the toughest debris any channel could offer while assuring reliability.

E&I Corp - Water Screens

E & I Corporation is committed to providing the highest quality Traveling Water Screen available. For the last quarter century, we’ve been backing up that claim with perfect performance records at installations like Westerville, Ohio.

E&I Corp - Catenary Grit & Heavy Media Collectors

The Catenary Grit Collector / Heavy Media Collector utilizes the Catenary in yet another application. This Catenary concept has the heavy duty chain and flights entering the chamber from the tail end of the chamber. The chain / flights are then pulled along the chamber floor, moving the settled grit or heavy media towards the inclined beach area. While continuing up the incline, the collection is dewatered before it is discharged into a container or other device. The transition, `Catenary`, between the chamber floor and incline is computer designed, using the weight of the material to be removed, along with the chain and flight weight.

E&I Corp - Horizontal Paddle Flocculators

Thru the use of state of the art computer programs, E & I Corporation is able to arrange the most effective configuration of Flocculator(s) to suit your needs. From paddle reel to turbine type, single stage to multi stage, the E & I Corporation Flocculator provides for the most efficient floc formation. Based on years of experience, the selection of materials, including fiberglass reinforced plastics and stainless steel, along with light weight tube shafts, quick removal flange connections to variable speed drives, E & I Corporation has a design to meet your requirements.

E&I Corp - Rectangular Collectors

For years, E & I Corportation has offered many material alternatives to increase the life of Rectangular Collectors. Thru the supply of complete new systems to the retro-fit of existing systems, E & I Corp has a solution to your problems. The usage of high strength plastics, reinforced fiberglass plastics to stainless steel components, E & I Corp can custom design a new system or retro-fit your existing system.

E & I CORP - Skimmers

E & I CORP offers a size and type of Skimmer for every application, from the simplest, most cost effective Lever Operated Skimmer to the more complex all stainless steel Helical (ribbon) type Automatic Skimmer. The choice of skimmer for a given application must be well thought out, along with considering the clients budget.