Eco Material Technologies Inc. products

Engineered Materials

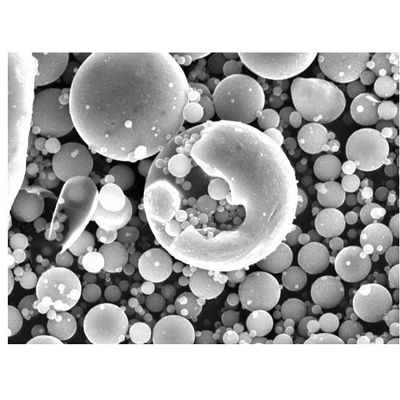

Eco Material - Model Celceram - Cellular Ceramic Materials

Celceram, or “Cellular Ceramic Materials” are comprised of complex inorganic solid and semi-solid calcium aluminosilicate glass spheres. Celceram has been successfully used as a functional filler in polyolefin, PVC, asphalt, reactive polyurethane, SBR and latex based products. Particle size distribution improves packing factors allowing for higher loading levels improving the physical charecteristics of the finished polymer system.

Eco Material - Model Celceram PV20A - Solid Calcium Aluminosilicate Glass Spheres

Celceram PV20A product is comprised of solid calcium aluminosilicate glass spheres. The source for these complex inorganic glass structures is the inorganic materials that have coalesced into spheres during the combustion process of coal in power generating processes. As such, all Celceram products are considered to be pre-consumer recycled content as defined by USGBC’s LEED program and the NSF140 standard.

Eco Material - Functional Fillers

As the leading manufacturer of bricks, clay tiles and concrete roof tiles, the Eco Material organization plays a major role in the industry. Added to that is the experience of Eco Material in developing and marketing fillers for concrete roof tiles, bricks, concrete blocks and wallboard. It’s a dual set of skills: developing effective alternative materials for building applications and knowing how to market them to the industry. Eco Material’s research and development in this area has led to the application of several patents.

Manufacturing Materials

Eco Material - Model Cementic - Cement

Cement manufacturers can choose this cost-effective, alternative raw ingredient, which has the added benefit of retarding cement set time. It gives cement manufacturers more ways to control costs and offer more competitive products.

Eco Material - Model TileBlend - Durable Material

TileBlend is a lightweight, durable material in the 1/4″ minus size range for use in concrete roof tiles.

Other Products

Eco Material - Model PozzoSlag - Green Low-carbon Cement

Eco Material Technologies has reengineered pozzolanic cement to make it react faster—matching the one-day performance of portland cement. PozzoSlag can replace a significant portion of the portland cement required to make high-strength, durable concrete. It is 20% stronger than portland cement in 28 days and continues to gain long-term strength. Moreover, PozzoSlag can be made at room temperature with virtually no emissions—a near-zero-carbon cement. While the mix design will depend on numerous factors, some customers are utilizing our pozzolanic cement at 60% or higher replacement. In addition, customers have been able to reduce the total amount of binder material required to hit their strength targets. Simply put, that means higher margins per job. PozzoSlag® has been commercially deployed in Texas, where it has been used in highways, roads, building foundations, airports, down hole cement, and precast concrete products.

Eco Material - Highly Reactive Pozzolans

The ongoing research program of the Eco Material Technology Development Group has resulted in a line of specified, high performance, Highly Reactive Pozzolan products that are used for a wide variety of construction applications and to optimize specific concrete properties.

Eco Material - Model Kirkland - Natural Pozzolan

Eco Material Technologies Resources has partnered with Kirkland Mining Company to develop its natural pozzolan mine near Kirkland, Arizona, 90 miles northwest of Phoenix. Kirkland’s high-quality natural pozzolans feature unique chemistry and morphology (physical shape and makeup) that make their performance in concrete competitive with, and often better than, the highest-quality fly ashes and natural pozzolans currently in the market (see table below).