ECOTEC, Ecología Técnica, S.A. products

Water Treatment

Ecotec - Lamellas for Settlers

Lamella settling is technology that has been successfully tried and tested to optimize the sedimentation process in a wide range of applications worldwide. ECOTEC has been using this technology for over 25 years, and thanks to its commitment to incorporating continuous improvements, ECOTEC provides solutions that ensure the most efficient lamellar systems.

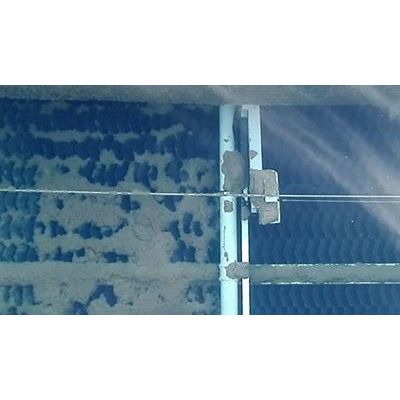

Laces - Automatic Cleaning System

LACES is a patented system designed to clean all lamellar channels installed throughout the surface of clarifiers. It is effective and thorough. It operates automatically once it receives the order to start the process from the plant operator. Once the settler cleaning process is complete, the equipment returns to its origin until it receives a new start signal. LACES cleaning system can be installed in tanks up to 60m long and 12m wide.

Ecotec - Compact Lamellar Clarifiers

Prefabricated lamellar clarifiers reduce space requirements characteristic of lamellar settlement, which results in cost reductions on civil works, and an installment that is easy and cost-effective. ECOTEC’s equipment is custom-made to adapt to the characteristics of each application. This optimizes performance, maximizes instalment space requirements and reduces the cost of equipment. The materials ECOTEC works with are plastic (polypropylene, GRP), and metal (carbon steel, stainless steel). One or more chambers can be added to form one single unit by mixing, coagulation, flocculation, etc.

Ecotec Bio-Cel - Submersible Membrane Modules for Bioreactors

The BIO-CEL membrane module is a reliable and efficient solution for the future. Its ultrafiltration process guarantees the best parameters in the final permeate, and its laminated configuration minimizes operation costs and maintenance. BIO-CEL combines the benefits of conventional flat membranes and hollow fiber modules without the shortcomings of each of these systems. Due to a membrane density (filtration surface per installed-m2) characteristic of hollow fiber modules and a backwash option under pressure, BIO-CEL preserves the open channel geometry characteristic of flat plates. BIO-CEL has taken one step further and has removed the frame which unblocks the boundaries and ensures the flow of membranes.

Model GRP - Modular Covers Ecomod

Built-in non-corrosive materials. Age-resistant. Low maintenance. Light-weight. Reduction of heat transmission. Colours according to customer requirements. Acoustic insulation.

Ecotec - Scrapers for Settlers

FINNCHAIN scraper systems incorporate lightweight and resistant parts in plastic materials, and stainless steel elements in points with maximum mechanical demand. All materials are corrosion-resistant. The reliability of this equipment, its durability and low maintenance requirements result in considerable savings in operating costs.

Ecotec - Aeration Diffusers System

Compression-molded membranes (including tubular membranes); these double the characteristics of mechanical and thermal resistance as compared to a conventional injection mold. Perforation by cutting- not puncturing- which increases efficiency and optimizes sealing during rest periods. Less dirt contamination and pressure loss. Maximum ratio Kg O2/Kw. Easy installation of the diffusers with quick-fit connectors. Easy replacement of diffusers and membranes.

Gas Treatment - Biogas Desulphurization

dBiox - Biotrickling Filter System

Biotrickling technology is based on a biological reactor with a scrubber-like washer (vertical alignment) fitted with extensive and effective inorganic packing which creates the habitat where microorganisms develop. The metabolic process of these microorganisms removes the polluting compounds contained in the gas stream. Biotrickling technology does not require chemical reagents, and if it does, it requires minimal quantities which reduces operating costs and eliminates the generation of toxic effluent, which would require further treatment.

Gas Treatment

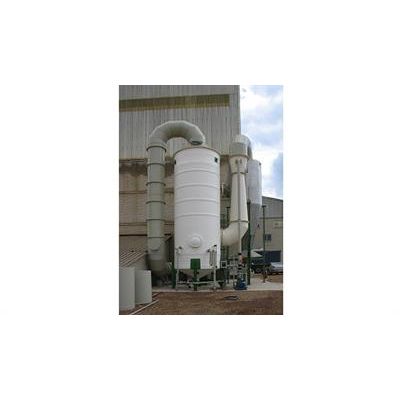

Ecotec - Gas Absorption and Neutralization System

In most industrial processes in which chemicals are produced and treated, emissions may be generated. Emissions of pollutants such as HCl, Cl2, SO2, HF, NOx, NH3, H2S, etc. must be treated and processed appropriately before being released into the atmosphere. ECOTEC has its own know-how and extensive experience not only in industrial applications, but also in the manufacture of equipment. ECOTEC’s processes incorporate innovative technology which achieves emission concentrations that comply with the current legislation regarding atmospheric emissions.

Dedusting Venturi Systems

Venturi systems are used to capture solid particles and also to wash medium/ high solubility gases. This process uses both physical dilution and chemical reactions. The high pressure drop generated in WET VENTURI is used to capture solid particles or liquid vesicles with a granulometry greater than 5 microns. Its effectiveness is directly related to the L/G ratio with a total pressure that can reach up to 6000 Pa. The system is generally comes with a cyclonic separator column and high efficiency drop separators.