Ecowair products

Lead Battery Recycling Ecowair Plants

Ecologic - Battery Breaker and Separation System

The most advanced system to break batteries, separate and recover the components. Presentation: coming out from the Italian long time experience on the fi eld, we are presenting, our recycling plant for the lead batteries. The environment safeguard and the materials recycle now is an obligation and a business opportunity. This thought is a must for all leaving people that want to preserve the nature, increase the life’ quality’ and -why not- save and earn money from waste. All battery producers and cars disposal have this opportunity. A lot of them, may be also you, are already doing that, and every day more people is asking to enter in this market. Also Governments are pushing and fi nancing the recycling of materials.

Ecowair - Lead Smelter and Refining Plant

Lead smelter and refining kettles. This part of the plant concern the supplying of a rotary furnace and kettles to melt grids/poles and Paste, to produce hard (Pb/Sb) and soft alloys. The plant is designed to work 24 hours day so you have to buy double smelting department. Here is indicated the complete day production system.

Ecowair - Lead Paste Desulphurization Plant

Eco Desulphurization Plant: The content of Sulphuric acid in the paste is considered a matter of pollution in itself and become more dangerous while the paste is put in the furnace to produce pure lead. During this phase the furnace release gases that are mainly constituted by SOx. Some countries rules require that the peak point never exceed the 200 mg/Nm3. Some others out of Europe, require that the daily average never exceed this data. So, a desulphurization system is required. This plant, using some reagents, special reactors and a crystallization units, neutralize the content of H2SO4 avoiding all environmental problems. In the other hand, the result from the neutralization plant is sodium sulphate Na2SO4 that is in detergent degree purity, that can be used in detergents or in glass production.

Water Treatment

Wastewater Treatment Plants

Between our equipments for the water and sewage treatment, we can list:

Mud Treatments Plant

Mud Treatments Plant

We are speaking of a bathtub with a mechanical mixing system or to air diffusion in order to avoid the birth of bad you smells.

Air Treatments

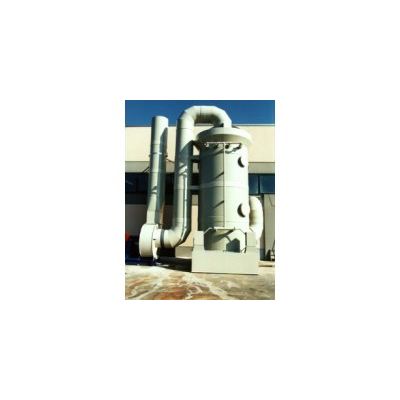

Humid Cleaners - Scrubber

The treatment of the air can regard various types of industrial production processes, characterized by emissions of injurious substances for the atmosphere. The scrubber it is a equipment that allow to pull down the concentration of substances in gaseous state, usually powders and micro polluting acids. These equipment finds application in the purification systems of smoke of many chemical plants.

Venturi Tower - Scrubber

It is a scrubber for the treatment of the air by means of chemical reaction with specific reagent. Generally it is realized in 2 sections so to increase the efficiency and grant the complete respect of rules. Section 1 - Venturi: the polluted air comes aspired in the scrubber where, for effect of the turbulence created in the throat by the high speed, a cleaning effect comes out thanks to the washing solution sprayed. Section 2 - Venturi: after the Venturi, the air passes to the washing tower where it is washed again in countercurrent with low speed and with one great contact surface. After this treatment the air goes in the atmosphere by the integrated fan. In the tower are install some demisters (alveolar packages, drop separators) in order to eliminate the dragging effect.

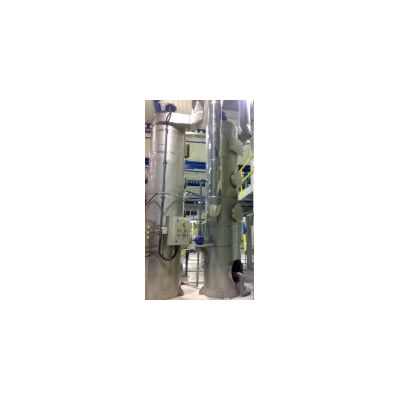

Stripping Tower

The sewage to deal it is pumped in the upper part of the tower and sprayed down to the bottom, there it meets the air flow in counter-current pushed by the fan. This phase allows of the passage from the liquid status to the gaseous one of the polluting. The air then passes through a chemical Scrubber for the cleaning of the polluting to reach the limits of law and released in the atmosphere. Using warm air the efficiency of the stripping tower can be increased obtaining reduction of the dimensions of the system.