EGESİS ÇEVRE TEKNOLOJİLERİ LTD products

Wastewater Treatment Equipment

DAF System (Dissolved Air Flotation)

DAF Dissolved Air Flotation system manufacturer EGESIS produces DAF units in its own factory. Get more information and pricing for DAF units. This Unit is used for the separation of floating and/or settling materials from the wastewater. It can be configured to operate before or without chemical treatment processes. Floating materials are removed by scraping paddle with a chain system, and the settled wastes are removed from the bottom with pumps. It is made of stainless 304/316 or St 37 + Epoxy or reinforced concrete as material.

Polyelectrolyte Preparation Unit

Poly-electrolyte preparation unit manufacturer EGESIS produces and exports wastewater treatment equipment. Please contact us for customizing and pricing. The production of the equipment is designed to accommodate capacities of 500, 1000, 2000, 3000, 4000 liters. The automatic polyelectrolyte preparation unit consists of three stages including dissolving, maturing and storage. For dry dosing, the powdered polyelectrolyte is automatically fed from the hopper into the mixing chamber with a rotating helix shaft. Tank is made of 304 or 316 stainless steel or St 37 + Epoxy and as the mixer blades and shafts are made of stainless steel.

Screens and Filters

Multi Rake Bar Screen

Multi rake bar screen production is done in our own factory in Turkey. Contact us for pricing and customizing options. Multi Rake Bar Screens are used to remove the undesired size solid materials that come to the treatment plant and pump stations as pretreatment processes. They can be manufactured in fine or coarse grades depending on the size of the solid material conveyed by the wastewater. These screens protect the equipment downstream from damages. The entire screen system is made of AISI 304 first quality stainless steel. The equipment can be manufactured to fit in to channels with depth of up to 15 meters and a width of up to 3 meters. The rakes are driven by the motor/gearbox assembly and carry the wastes on the screen bars upwards. With a scraper blade located at the top of the screen, the carried wastes are scraped and dropped into the container or on to the conveyor. The equipment does not have any moving gear parts under the water level thus the risk of jamming is minimized.

Sleeve Bend Screen

Sleeve bend screen manufacturer EGESIS produces all wastewater equipment in our own factory in Turkey. Contact us for pricing mad more details for sleeve bend screen. It is a preferred equipment due its relatively less service and maintenance costs, require power to operate, saving labor and energy. It is used for the removal of smaller solid particles organic or inorganic originating from the production of industrial wastewater rather than domestic wastewater. In this way, it extends the service life of pumps and similar equipment used in the system hence reduce the pollution load of the wastewater treatment plant.

Scrapers and Clarifier

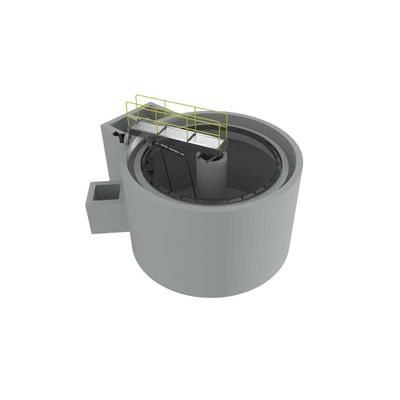

Rotating Sludge Scraper

Contact us for rotating sludge scraper prices and customization. We manufacture and produce wastewater equipment in our factory in Turkey. The rotary scraper bridges are the equipment used in clarifiers (aka settling basins, pool). They are used to gather/collect the settled sludge into the center cone of the clarifier. The sludge collected in the cone is then recycled to the aeration basin and/or delivered to the sludge thickener basins. The bridge body is generally made of St 37 + Epoxy Painted or galvanized. It can also be manufactured from 304 and 316 quality stainless steel upon request. Corrosion resistant cloth rubber is used in the bottom scraper. Corrosion resistant movable Delrin wheels are used where the scraper plates are connected with rubber scrapers. The equipment performs bottom scraping by rotating around its base located in the center of the cylindrical pool.