- Home

- Companies

- Enotec GmbH

- Products

Enotec GmbH products

Analyzers - O2 Analyzers

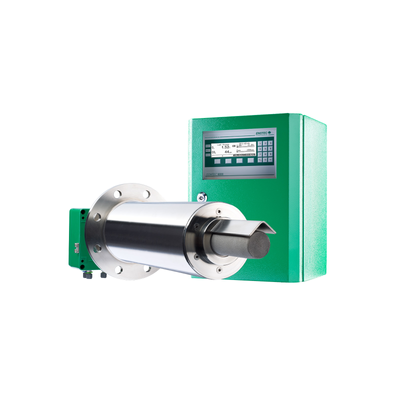

Enotec - Insitu O2 Analyzer

ENOTEC produces oxygen analyzers for fast and precise combustion monitoring. OXITEC analyzers are developed according to ISO 9001 standards and are manufactured entirely in-house at the company headquarters in Germany.

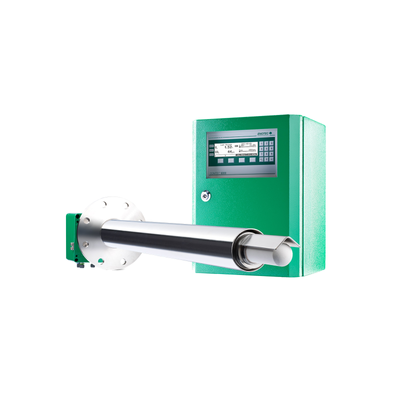

Enotec - Robust O2 Analyzer

The OXITEC GasEx is a robust oxygen analyzer that skillfully combines the renowned reliability and quality of OXITEC analyzers with the high safety standards of explosion-protected zones for maximum plant safety.

Enotec - Durable O2 Analyzer

The extractive OXITEC 500E analyzer incorporates the same sensor technology used in the proven OXITEC 5000 analyzers. In combination with an ENOTEC gas sampling and conditioning system, the OXITEC 500E measures the oxygen content of moist and dry flue gases down to a detection limit of 1 ppm.

Analyzers - O2 / COe Analyzers

Enotec - Insitu O2 & Coe Analyzer

COMTEC 6000 is an in-situ gas analyzer for measuring oxygen and COe (the sum of unburned molecules such as carbon monoxide, methane, or hydrogen) in flue and process gases. This enables redundant measurement of both gases with high accuracy in real time, enabling efficient combustion optimization. This is achieved by combining the MXP sensor for COe analysis with the MLT sensor technology for calculating the oxygen content.

Enotec - O2 & COe Analyzer

The explosion-proof COMTEC 6000 GasEx analysis system reacts immediately to changes in flue gas composition and is ideal for safe and accurate measurements of oxygen and CO2 in refineries or similar areas with a risk of explosion (Gas Ex Zones 1/2).

Enotec - O2 & COe Analyzer

The standard for use in dust explosion protection zones 21/22 is called COMTEC 6000 StaubEx. In line with the tough requirements associated with use in such dusty environments, the ATEX certification meets Class II 2D Ex tb IIIC T133°C/T141°C Db.

Enotec - O2 & COe Analyzer

The self-monitoring SILOTEC 8000 was developed for ATEX Zone 20 gas analysis in silos. The simultaneous measurement of CO2 and O2 enables the detection of smoldering fires and can trigger and monitor inerting in these cases.

Analyzers - O2 / H2O Analyzers

Enotec - O2 / H2O Analyzer

Drying processes are among the most energy-intensive in manufacturing processes, regardless of whether it is the production of plasterboard or the processing of tobacco plants. Fast and reliable measurements during the drying process reduce the required time and allow for optimization of energy consumption. Due to its in-situ measurement method, the AQUATEC 1000 analyzer is superior to conventional systems with extractive methods in terms of measurement speed. Sensors from ENOTEC have already proven themselves in countless applications around the world.

Gas Sampling - Probe System

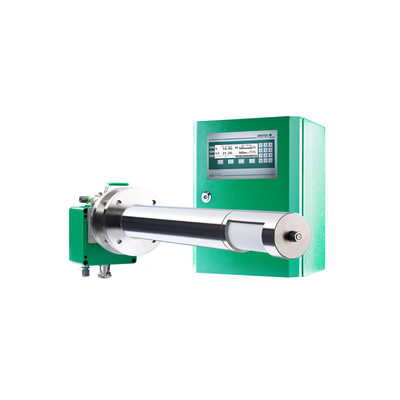

Enotec - O2 & COe Analyzer

The explosion-proof COMTEC 6000 GasEx analysis system reacts immediately to changes in flue gas composition and is ideal for safe and accurate measurements of oxygen and CO2 in refineries or similar areas with a risk of explosion (Gas Ex Zones 1/2). The ATEX certifications (II 2G Ex db IIC T3 Gb), successfully completed by a German testing institute, apply to all analyzer components, including those directly exposed to the flue gas. This certification creates confidence in plant safety and is coupled with the convincing quality of ENOTEC products, which consistently withstand the challenges of aggressive process conditions.

Systems Solutions

Enotec - Gas Extraction System

The CEMTEC gas sampling system was developed for continuous flue gas analysis in cement kiln inlet chambers and in other extremely dusty, high-temperature processes such as lime works. The goal is to increase product quality with reduced fuel consumption and simultaneously reduce harmful emissions.