ENTEX Rust & Mitschke GmbH products

Laboratory Extruder

ENTEX - Laboratory Extruder

Explore your ideas and develop your products! The smallest ENTEX extrusion system is the ”30” series laboratory extruder. This unit’s size makes it possible to perform series of tests for formulation and product development at laboratory scale. Thanks to its ease of use and the flexibility that results from its modular structure, the “30” series laboratory extruder can be quickly configured for individual applications. With peripherals such as dosing units, side feeders, degassing systems, pelletisers, etc., it is possible to create complete extrusion lines. Integrated sensors measure energy inputs, pressure and temperature so that the process can be analysed and the product quality assessed.

Pilot Systems

ENTEX - Planetary Roller Extruder

Our “70” series extruders can be used for product development, process optimisation and the production of materials for customer samples. Every step in the process for production machines can be reproduced at pilot scale. The process section and machine frame are modular, making it possible to expand or reconfigure the system as necessary. Additional peripherals can be easily connected and integrated into the control system. To ensure the necessary material quality, the process is regulated by setting process parameters, recording throughputs and energy values, and measuring pressure and temperature amongst other things.

Production Systems

ENTEX - Planetary Roller Extruder

The configuration of the Planetary Roller Extruder is tailored to the individual production process. Thanks to a modular system that is able to accommodate each individual step in the process – such as material feeding, melting, mixing in, homogenisation, degassing, etc. – and corresponding peripherals, Planetary Roller Extruders can be used to perform, optimise or replace a wide range of production processes in the adhesives, plastics, rubber, chemicals and food industries. The modular concept makes a variety of process section lengths possible for all PRE unit sizes listed below. The maximum length in each case depends on the unit size, process, expected central spindle torques, and the materials used, and must be individually determined. Formulations are administered and process parameters set using the ergonomic control system, while the process is monitored by integrated sensors.

Tempering Systems

Dynamic - Temperature Control System

The modular Dynamic 140 – 220 series uses water (pressurised) as a heat transfer medium.

AngioDynamics - Temperature Control System

The modular Dynamic 300 – 430 series uses thermal oil (pressurised > 350 °C) as a heat transfer medium.

Thermodynamics

ENTEX - Extruder Tempering

Precise and efficient temperature control. The importance of heating and cooling technology cannot be overestimated – and not just for extrusion processes. It is a key determinant of product quality, and plays a major role in resource conservation and economic efficiency.

ENTEX has developed its own temperature control units to ensure that its Planetary Roller Extruders enjoy top of the line tempering. In fact, these units are now also being used outside the field of extrusion technology.

Additional Products

ENTEX - Compounding and Compression

ENTEX strainers are deployed to reliably remove impurities from plastics, adhesives and rubber compounds. Interchangeable filter screens make it possible to perform rapid cleaning while reducing production downtimes. The ENTEX design features thin walls between the heating/cooling media and the material in the extruder cylinder. This allows for the precise temperature control necessary to process even sensitive materials like PVC and biopolymers.

ENTEX - Pelletising Systems

An all-round solution: Radial pelletising systems from ENTEX. Various types of technical pellets are frequently required as precursor products for the manufacture of all manner of plastics and recycled materials, as well as for food, animal feed, etc. The technical properties required for subsequent processing – such as diameter, length, weight, surface quality, residual moisture, etc. – are determined during the pelletising process.

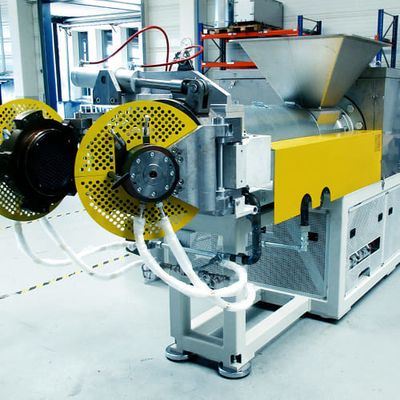

ENTEX - Single-Screw Extruders

ENTEX single-screw extruders are often used in conjunction with ENTEX Planetary Roller Extruders as either an upstream or downstream stage in the process. An example of an upstream use is for feeding recyclates, while examples of downstream deployments include pressure build-up and discharge into moulds. As with ENTEX Planetary Roller Extruders, the tempering takes place via fluid media. Thin walls between the tempering medium and the material in the cylinder enable excellent temperature control. Drawing on a wealth of Planetary Roller expertise, special screw geometries have been developed that are especially well suited to degassing volatile substances.