Envipro Engineering Pvt. Ltd products

Air Pollution Control Equipment

Envipro - Dust Extraction System

Envipro Engineering Pvt Ltd is a Pune based Dust Extraction System Manufacturers, With the aid of our competent team, we fabricate an exquisite range of technically advanced dust extraction system. In the entire manufacturing process, we use high-quality raw material, latest machines, equipment, and tools. It is also termed as electro-extraction.

Envipro - Pulse Jet Bag Filters

We are leading Bag Filter Manufacturers in India, As far as the users are concerned, these Pulse Jet bag Filters are basically used in air pollution control equipment. The finest part of this system is that it can filter heavy dust burdens and achieve desired collection efficiency at high temperature. Reverse pulse jet bag filter serves for dry separation of dust from waste gas. In order to ensure quality, we follow industry standards in manufacturing the products by using the high-grade material. Our patrons can avail these Industrial Pulse Jet Bag Filters available at highly affordable rates.

Envipro - Wet Scrubber

We are leading manufacturer of wet scrubber, we are offering a wide range of Wet Scrubber, which is designed to control and curb the toxic fumes from the various processes. Dust laden gas enters the venturi and instantly make contact with the tangentially introduced scrubbing liquid swirling down the venturi’s converging walls. At the venturi throat, the gas and liquid streams collide and the liquid breaks down into droplets which trap dust particles.

Envipro - Venturi Scrubber

We are leading Venturi scrubber manufacturers, With the aid of our competent team we are able to manufacture the wide variety of Venturi scrubber for the clients.

Envipro - Packed Tower Scrubbers

We are pinnacle in the list of companies offering wide array of packed tower scrubber manufacturers for the patrons. This wet type scrubber removes fumes and odors during operation. We fabricate this using the finest quality of raw material procured from the authentic vendors of the market.

Chemical Process Equipment

Envipro - Thermal Sand Reclamation System

We are Thermal Sand Reclamation System Manufacturers. Day by day, we all are very much cautious about the environment globally, each country is trying to have good atmosphere, Due to industrial growth in various sector including Foundry and auto sector in which ample quantity molding sand is used. The used sand in molding is just thrown away in to atmosphere/ or Land filled, causing huge pollution. The thrown sand can be reused if processed in to the thermal sand reclamation plant. Thermal sand reclamation of waste foundry sand can be realized cost effectively. The resultant sand is generally cleaner than new sand and results in improved casting quality. The 5% sand that is lost during the reclamation process is free of organic contamination and is collected in a cyclone and dust collector.

Envipro - Spray Dryer System

We are Spray Dryer System Manufacturers. Spray drying Technology, which is mostly used to extract powder from the Liquid or slurry by applying Hot air on the sprayed Droplet of Slurry or Liquid. Due to the hot air, the water gets evaporated to form the feed and converted into powder. This is the preferred method of drying of many thermally-sensitive materials which are used in foods, pharmaceuticals, agro and much more.The spray dryers are co-current and countercurrent types.

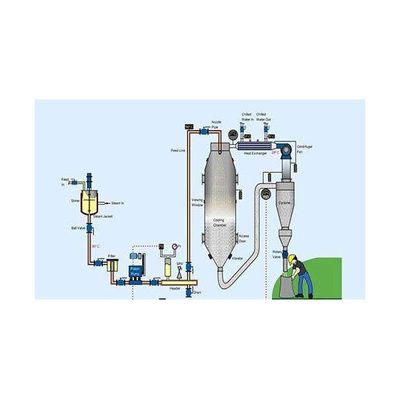

Envipro - Spray Cooler

Spray Cooler is technology adopted for the material of wax category. The material is to be sprayed is kept in molten condition in the steam jacketed/hot water jacketed vessels. From the jacketed vessels it is transferred to the feed vessels by the jacketed feed pumps with the help of positive displacement pump. (It is also steam jacketed) The molten mass is pumped & sprayed in chamber & droplets are converted to fine particles. At the same time the cold air is passed on this molten mass through the uniform air distribution system in the spray chamber. The heat of the fine particles is liberated & particles are cooled. The spray cooled particles further passes to the spray cooler conveying duct, cyclone, Secondary Cooler etc.