Environmental Protection, Inc. (EPI) products

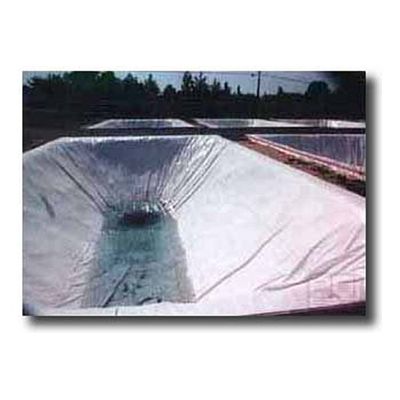

EPI SunTech - Geomembrane

SunTech PVC is geomembrane that is designed to withstand the sun`s harmful radiation and still give you all the characteristics that make PVC one of most reliable and easy-to-install geomembranes on the market. SunTech PVC is easy to install, especially for installations with multiple panels that require field seams. SunTech PVC can be seamed together with an adhesive. No thermal welding is required for installation.

EPI - Reinforced UltraTech Flexible Geomembrane

The following is a specification for EPI`s Reinforced UltraTech geomembrane and is recommended for use as a guideline in specifying lining and cover membrane.

EPI - PVC for Potable Water

EPI fabricates 40 mil thick potable water grade PVC geomembrane liners for all your food processing needs.

EPI UltraTech - Geomembrane Liner

A single-ply EIA membrane compounded for hydraulic containment, UltraTech® flexible geomembrane possesses proven characteristics. Because of its unique composition, UltraTech® naturally provides exceptional weather ability, resistance to oils, chemicals and grease. Some of its other unique characteristics include a flexibility over a broad temperature range and its high tensile strength and elongation properties.

EPI - Polypropylene (PP) Geomembranes

Reinforced Polypropylene provides a versatile flexible geomembrane liner. The unique three-ply construction with a combination of custom fabric reinforcement encapsulated by extruded high-performance polypropylene provides a strong, highly chemical resistant liner. The chemically inert polymer is modified to provide many specialized properties that include excellent flexibility, low thermal coefficient of expansion and contraction, outstanding dimensional stability, wide temperature range for excellent seaming and good chemical resistance in exposed liner applications. All factory and field seams are thermally welded.

EPI - PVC Flexible Geomembrane

EPI’s PVC fabricated liners are of single-ply construction, featuring Polyvinyl Chloride as the predominant polymer. Only first-quality virgin resins are used and every material used either meets or exceeds ASTM D 7176 minimum specifications* for materials and ASTM D 7408 minimum specifications for seam strength.**

EPI - State-of-the-art Geomembrane

XR-5 is a state of the art geomembrane compatible with a wide range of harsh liquids. It is an extremely tough woven synthetic fabric of DuPont Dacron Polyester which has been molecularly coated with sophisticated compounds that are minimally degradable in adverse environments. This design eliminates liner failure caused by `wicking` as can be experienced by laminates. Delamination is also impossible as XR-5`s exclusive molecular primers saturate its woven fibers bonding the substrate and coating compound into a single system. XR-5® also exhibits impressive dimensional stability, tensile strength and puncture resistance. Maximum strength to weight ratios and superior flexibility are other qualities which XR-5® delivers. In plant fabrication and on-site installation go quickly. Time and money are saved and quality is assured.

EPI - Reinforced Polypropylene Geomembranes

Reinforced Polypropylene provides a versatile flexible geomembrane liner. The unique three ply construction with a combination of custom fabric reinforcement encapsulated by extruded high performance polypropylene provides a strong, highly chemical resistant liner. The chemically inert polymer is modified to provide many specialized properties that include excellent flexibility, low thermal coefficient of expansion and contraction, outstanding dimensional stability, wide temperature range for excellent seaming and good chemical resistance in exposed liner applications. All factory and field seams are thermally welded.

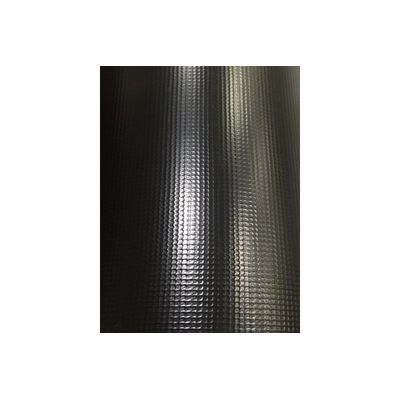

EPI - Linear Low Density Polyethylene - Textured

If you require increased frictional performance, flexibility and elongation, Linear Low Density Polyethylene (LLDPE) - Textured Geomembranes are the best product choice. Its superior textured surface allows for increased friction between the two layers and the design of steeper slopes.

EPI - Scrim Reinforced Polyethylene (Textured or Smooth)

Scrim Reinforced Polyethylene consists of two sheets of high strength polyethylene film laminated together with a third layer of molten polyethylene. Providing a higher tear resistance and increases service life. The black outer layer contains carbon black to enhance outdoor life.