Environmental Protection Technologies Ltd. (EPT) products

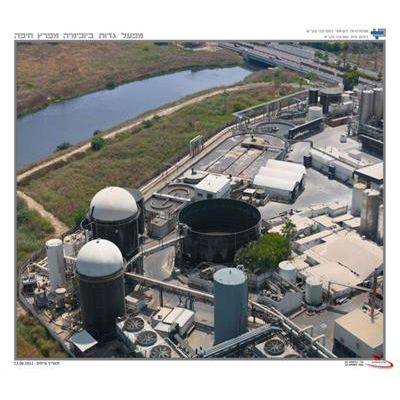

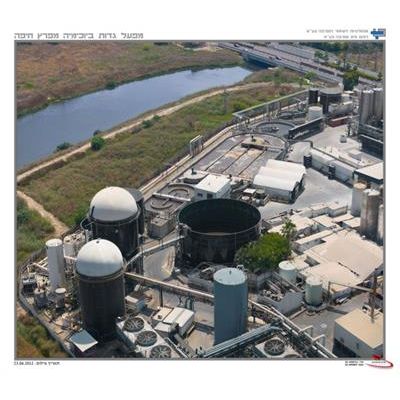

Aerobic Treatment

EPT - Biological Nutrient Removal System (BNR)

Biological Nutrient Removal (BNR) process removes total nitrogen (TN) and total phosphorus (TP) from wastewater through the use of microorganisms under different environmental conditions in the treatment process.

EPT - Dual Sludge Wastewater Treatment System (DSS)

The Dual Sludge System (DSS) technology employs two consecutive fully-independent sludge systems. The first sludge system is usually CAS (conventional activated sludge) followed by CAS or MBR (Membrane Bio-Reactor) system.

EPT - Membrane BioReactor (MBR)

MBR (Membrane Bio-Reactor) is a profound technology, dating back to the late 70`s, which combines secondary and tertiary treatment by activated sludge and UF (Ultra-Filtration) membranes for absolute solids/liquid separation.

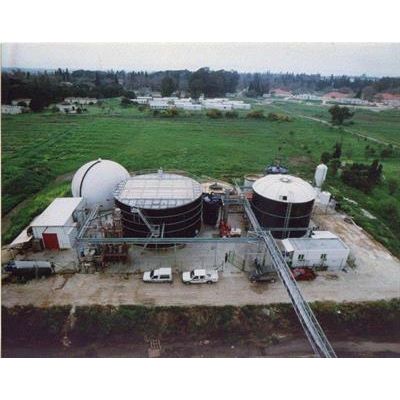

Anaerobic Treatment

EPT - Biobulk Technology

The biobulk technology includes CSTR (Completely Stirred Tank Reactor) for anaerobic treatment. It may be designed with downstream solids separation step, for example - secondary clarifier, or as a once through reactor for high solides waste. To ensure that the wastewater is in constant contact with the anaerobic biomass a good design of the mixer and the vessel should take into account.

EPT - Expanded Granular Sludge Bed Reactor (EGSB)

The Expanded Granular Sludge Bed (EGSB) reactor is an anaerobic treatment technology where space constraints exist. The reactor is design tall and slender with a special internal configuration. The high pressure reactor can save the biogas holder or the biogas compressor, i.e. reduction in the capital and maintenance costs. This technology can be very highly loaded with 25-30 kg COD per m3 per day, compared to others anaerobic technologies (UASB and biobulk for example).

EPT - Upflow Anaerobic Sludge Blanket System (UASB)

The Upflow Anaerobic Sludge Blanket (UASB) is one of the more technologically advanced high-rate anaerobic wastewater treatment systems. It is capable of removing 85-90% of the influent COD at relatively high loading rate of 10-15 kg COD/m3/d with a short hydraulic retention time (HRT) of 4 to 8 hours and low footprint. Furthermore, it can handle successfully with high fluctuation of raw wastewater organic loading.

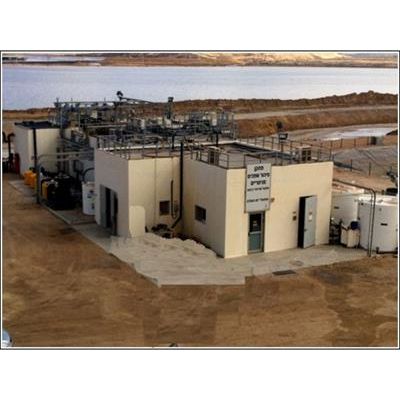

Physical/chemical Treatment

EPT - Water Treatment Crystallizer

The Crystallizer is a fluidized bed pellet reactor originally designed for softening purposes of drinking water. It is used worldwide for the crystallization of a variety of metals carbonates, phosphate, halides, sulfate and sulfide.

EPT - Dissolved Air Flotation System (DAF)

DAF (Dissolved Air Floatation) system is used for final clarification and FOG removal, in which micro air bubbles attach and float flocculated particles and suspended solids to the water surface, where it is skimmed for final removal.