- Home

- Companies

- Envitech, Inc.

- Products

Envitech, Inc. products

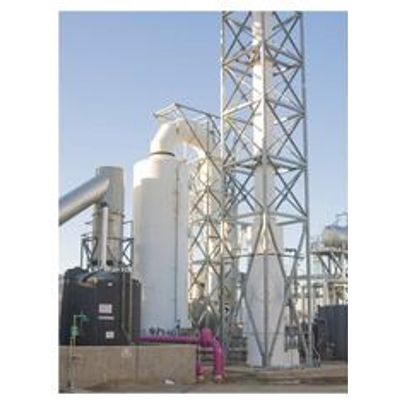

Envitech - Quencher

The Envitech quencher is a proprietary design that uses makeup water and a low-pressure-drop Venturi to cool hot gases by evaporating water into the gas. The Venturi provides turbulence to atomize the makeup water and saturate the gas while also collecting large particulate and absorbing acid gases. High turbulence provides an effective means to saturate the gas over a broad turn-down range.

Envitech - Packed Bed Scrubber

Envitech`s high-efficiency, low pressure drop packed bed scrubbers use random or structured packing, a mist eliminator, and a liquid distribution system to remove acid and toxic gases through a process of absorption and neutralization. The packed media provides mass transfer area to absorb acid gases such as SO2, HCl, NH3, and other gases.

Envitech - Direct Contact Condenser

A direct contact condenser transfers heat from a gas to a liquid. The liquid and gas come in direct contact, which maximizes the thermal efficiency. Direct contact condensers may be spray towers, where liquid is sprayed into a gas stream; packed bed towers, where liquid is sprayed on top of packed media to enhance thermal transfer; or tray towers, where liquid is injected on top of a mass transfer "tray" that contacts the gas with the liquid.

Envitech - Venturi Scrubber

Envitech`s Venturi Scrubber efficiently removes particulate. The inlet can handle gases up to 230ºC (450ºF). Higher inlet temperatures can be accommodated with the addition of a quencher to saturate the gas before entering the Venturi.

Envitech - Entrainment Separator

Envitech`s high-efficiency, multi-stage waveform Entrainment Separator effectively collects the fine drops, while operating at a low pressure drop. This is extremely important because the presence of entrained liquid adversely affects performance.

Envitech - Wet Electrostatic Precipitator (WESP)

Envitech’s wet electrostatic precipitator (WESP) uses electrostatic forces to remove particulate. It is used to treat gas streams with sub-micron particulate, aerosols, or fumes. These can include heavy metals such as lead, arsenic, or cadmium, condensed acid aerosols like sulfur trioxide (SO3), or condensed volatile organic compounds (VOC’s). The use of electrostatic forces minimizes energy costs compared to Venturi scrubbers or baghouses, which require large amounts of energy to overcome resistance to air flow. Wet electrostatic precipitators are used in a wide range of applications including, hazardous and medical waste incinerators, metals refining, sulfite pulp mill recovery boilers, copper roasters, sulfuric acid plants, and wood dryers including oriented strand board (OSB), medium density fiber board (MDF), or pellet mill dryers.