EPM - Environmental Project Management (Contracts) Ltd services

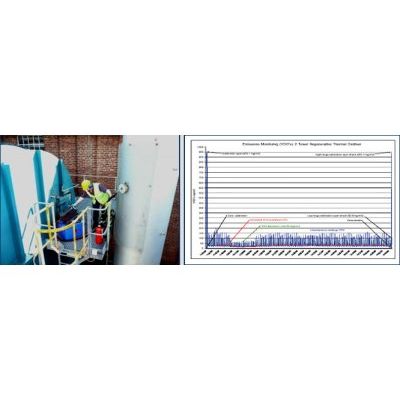

Stack Monitoring

When an installation is complete, EPM service doesn`t stop there. We also offer various valuable ongoing services to Clients to ensure you are operating safely, efficiently and effectively. An essential part of installing abatement plant is to ensure that they operate effectively within the P.E.L. (Permitted Emission Limit) as detailed within the process guidance note. Both as part of the acceptance testing and also annual monitoring, the emissions of VOC (Volatile Organic Compounds), CO and NOx must be monitored over a minimum 5 hour period. The initial task is to establish a S.S.P. (Site Specific Protocol) to be agreed with the Regulatory Authority. Additionally, a Risk Assessment has to be made because of the inherent hazards involved. EPM are members of the STA (Source Testing Association) and have MCerts certified personnel for stack emissions monitoring.

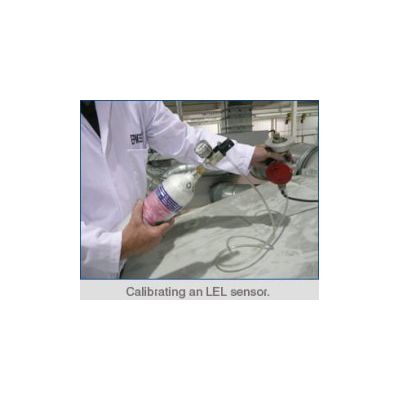

LEL Calibration

In recent generations of press designs, gas monitors are installed to constantly monitor solvent levels within dryers and exhaust ductwork. If not already installed, then we would install them as part of the optimisation process. The solvent is measured as a function of safety as %LEL (a percentage of the lower explosive limit) normally using catalytic or infra red sensors. Since they are important safety devices, it is essential to establish and maintain a calibration regime. We recommend calibration every 3 months when installed in dryers not only because of their importance but potential for contamination and reduced sensitivity.

COSHH Assessments

Using solvents in printing results in exposing Operatives to hazardous vapours. The Control of Substances Hazardous to Health Regulations (1994) (COSHH) includes Regulation 7 that requires LEV`s ( Local Extract Ventilation) to be installed to control the risk. Regulation 9 requires that the control measures be assessed every 14 months maximum to ensure that they are operating correctly and efficiently to minimise the exposure risk.

General Servicing

An effective and efficient operation can only be maintained if the system operates correctly. This can include the following: Dampers and explosion panels being checked and lubricated, System alarms functions being checked, Checking and calibrating pressure switches and transducers.

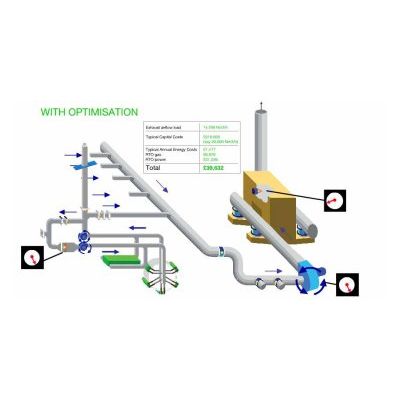

Dryer Optimisation

The size and running cost of solvent VOC abatement plant depends on the process load. Typically, press dryers have large volumes of exhaust with low concentrations of solvent. Without optimisation, the abatement could be considerably larger and significantly more expensive to run. The effect is illustrated below. Therefore, it is essential before considering abatement plant the process loading must be examined carefully. An example of an installation with 5 flexo presses having an existing airflow of 45,000 Nm³/h: