Esko Pacific Sales Ltd products

Flow Meters & Rotameters

Model ELF - Purge Flow Meter

The model ELF purge meter is a compact, customizable flow meter designed for the measurement of small flows of liquids or gases. Custom materials, scales and scale markings for various flow applications are available at a competitive price. Modular design principles allow users to specify body material, flow range and media, O-ring materials and optional hand knob. ESKO offers custom scale markings and calibration for non-standard liquids and gases. The ELF is often paired with the model EFR3 constant flow regulator also designed and built by ESKO for maintaining flows in applications where supply or back pressure varies. Metallic parts on the model ELF are solid and reliable SS316 construction. The model ELF is often utilized in bubble tube level applications, density measurement, and pressurized instrument enclosures.

Model ELC - Purge Flow Meter

Seal Water Meters

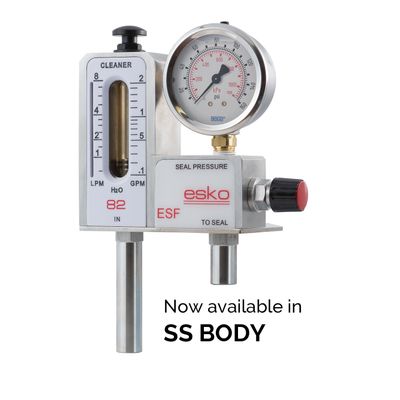

Model ESF - Seal Water Meter

The model ESF sealing liquid monitor is designed for applications where uninterrupted seal water flow is required for cooling and lubrication. The ESF is compatible with all seal types and intended for water flows up to 3.5 gallons per minute. ESKO seal water monitors are also available in a dual tube model EDF for double mechanical seals to monitor the water going in and out of seals. Effectively managing seal water use can result in cost savings on water consumption, reduced downtime, and optimized seal life and reliability.

Model EDF - Seal Water Meter

The model EDF is a dual flow seal water monitor with many of the same design features as the ESKO ESF seal water monitor. In typical applications, the EDF is designed to give an indication of water as it enters and as it exits a double mechanical seal to ensure the seal is constantly cooled and lubricated. These meters are often mounted on a stand (also supplied by ESKO) near the pump.

Oil Lubrication

Model EMO - Medium Range Meter

Ideal for medium size flows up to 2.5 GPM / 10 LPM in industrial applications. Model EMO meters are designed with a built-in flow control valve on the outlet. In oil lubrication applications, the flow control valve on the outlet allows for full-pressure oil flow through the flow tube feeding oil to a bearing. This design is optimal for accurate measurement of bearing lubrication. The base Model EM is available with no flow control valve and the Model EMI features a flow control valve on the inlet. Like the base model single tube Model EM flow meter, Model EMO meters feature robust stainless steel side plates, several choices of end block materials, float materials, and heat resistant Grilamid or impact-resistant PSU tubes. The Model EMO is also available in a multi-tube model configured for lubricating oil monitoring systems. A large selection of flow ranges with custom calibration for different operating conditions is available.