Estruagua products

Large Solids

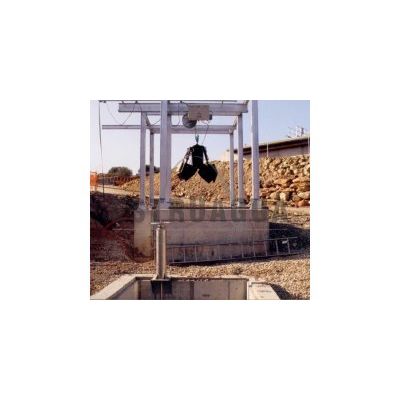

Hercules - Model CP - Bivalve Electro Hydraulic Grab

Valves.- two of special design and great robustness, built with electro welded plates in carbon steel of A/42-b quality, provided inside with reinforcements.

Overflow Screen

Eagle - Hydraulic Spillway Screen

Floating material retention in sewage structures. The pollution of superficial water resources, by the combination of the sewerage system and in part also by storm water tanks, consists of solids which are present in the residual water. This includes a wide variety of dissolved and semi dissolved fibers and solid substances, with different structures and specific weights (plastic shreds, sanitary towels, diapers, preservatives, fecal matter, paper, etc.).

Apache - Model TAC-01 - Circular Spillway Screen

Specially designed for those spillways or storm tanks of not very high flows or dimensions. Excellent QUALITY/PERFORMANCE/PRICE relation. Robust construction totally in stainless steel Aisi 304 or 316 quality. The equipment consists of four cleaning arms, adjustable to the filtering screen two arms have anti wear nylon cleaning brushes and the other two in stainless steel. The valid meshes for this equipments vary between 1.00 mm and 10.00 mm, the execution is in triangular or perforated profile depending on the mesh. Driven by a motor reducer located in the top part of the equipment and out of reach of the flow to be treated, the TAC-01 screen filter the excess water and does not let the solids go trough, the spinning sense of the sweeping arms is contrary to the watch needles.

Hurricane - Model TAT-01 - Helicoidal Spillway Screen

The Screens spillway which its function is to separate the solids present in the water to be treated in a timely manner because its function occur in emergencies situations letting pass the water through it and holding the captured solids with the clear path of light according to the design. (Normally between 3 and 6 mm). We can found these equipment at the entrances of wastewater treatment plants, pumping stations, etc . Its manufacture becomes from carbon steel, stainless steel AISI 304, 316, duplex, super duplex, etc . Flow rates from a minimum of 20 m3 / h and minimum diameters of 160 mm thread.

Large and Medium Solids

Titan - Model DT-011 - Automatic Chain Screen

The objective of screening, amongst others, is to separate and to protect the station or process of the possible unseasonable arrival of large objects, to separate and evacuate easily the voluminous matters, etc.

Hidrorake - Model DA-011 - Hydraulic Automatic Screen

In order to try to solve the separation problems, an Automatic Screen System with the following advantages was developed:

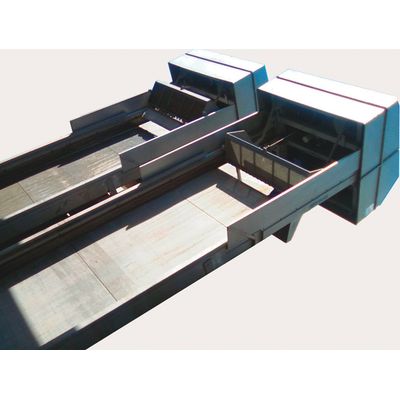

Cablerake - Model DB-011 - Automatic Cable Screen

The Automatic cable screen CABLERAKE is prepared to work continuously or in hard conditions in channels of width above 800 mm. As a correct installation of such machinery, it is recommended to introduce it in channels of very high deepth, in which we cannot implant our hydraulic or chain screens. Such mechanic equipment are constituted by the following elements.

Small Solids

Pegasus - Model PRO - Perforated Filtering Screen

he Perforated filtering screen PEGASUS PRO i s an evolution of our self-cleaning sieve filter PEGASUS. This new equipment replaces the filter elements in longitudinal section through perforated section, thereby increasing the efficiency of solid removal since its filtering screen is perforated. Perforated filtering screen PEGASUS PRO ® in MBR installation, light 3.00mm

Pegasus - Model TS-01 - Filtering Screen

The first Filtering screen PEGASUS ® step screen was installed in Alicante, in October, 1992 in Rodelco, S.A., a private company of the meat sector. The performance and almost null maintenance results, constituted together with the by- pass channel elimination, a new concept in step screen. The characteristic that identifies the PEGASUS ® step screen is the design of the hook and of the transmission-cleaning wheel. This development began in 1989 and during these years it has been improved until it has reached the exact measurements that guarantee the best performance and the maximum life. In the following pages the reasons are explained.

Basketpro - Model TCT-020 - Basket Conveyor Screen

As the first element of the mechanical pre treatment , the separation equipment has a key importance in the purifying process, either in a waste water treatment plant as for example in the treatment of process water. The objective consists in achieving the maximum grade of separation under the hydraulic conditioning. In waste water treatment plants it is often demanded the devolution of the soluble matter to the flow of water in order to incorporate that organic substrate into the biological stage. The hygiene in the functioning, the reliability in the operation and the lower possible maintenance are other considerations that have a higher importance each day.