- Home

- Companies

- EVATHERM Ltd.

- Products

EVATHERM Ltd. products

Evaporators

Evaporation and Crystallization Main Process Technology

The evaporation and crystallization technology belongs to the most energy consuming processes in the base chemical industry. Therefore it is decisive to choose the most suitable process considering all the environmental and energy aspects in order to ensure the economical feasibility for a long term. The following short introduction shall give a brief overview of the basic processes and its applications.

Falling Film Evaporator

The falling film evaporator is particularly used in application, when the driving force between heat transfer medium and liquid is small. In a falling film evaporator with separate vapor body and heat exchanger the liquor is fed into the top liquor chamber of the heat exchanger where it is distributed to each tube.

Rising Film Evaporator

A rising film evaporator is primarily used to concentrate non-salting and non scaling liquors.

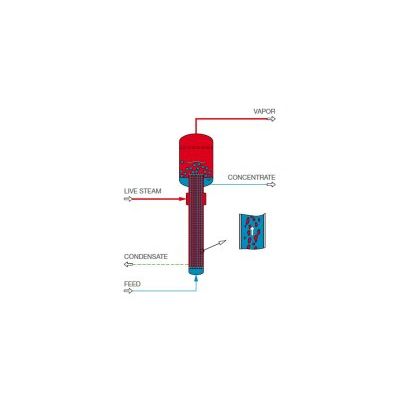

Model MSMPR - Forced Circulation Evaporator

The MSMPR (Mixed Suspension, Mixed Products Removal) and the MSCPR (Mixed Suspension Classified Products Removal) are the classical devices to crystallize salts. As the name implies, the liquor in a forced-circulation evaporator is pumped through the tubes to minimize tube scaling or salting when precipitates are formed during evaporation.

Growth Type Crystallizer

Where crystal growth is critical, our growth type crystallizer can be applied.

Main Processes

Multiple Effect Evaporation Plant

If raw brine as feed and low pressure steam for heating is available, the Multi-Stage Vacuum system is preferred. Purity levels can be set by the application of the adequate elutriation and purge systems.