- Home

- Companies

- Fab-Tech Engineers

- Products

Fab-Tech Engineers products

Pulverizer

Fab-Tech - Spice Pulverizer for Industrial Use

The spice pulverizer by Fab-Tech Engineers is designed for efficiently crushing and grinding a wide range of materials including spices, chemicals, Ayurvedic herbs, and agro-products. Capable of pulverizing materials to a 60-80 mesh, this robust machine allows for variable capacity ranges from 25 to 1000 kg/hr. It offers an optional AVM pad which minimizes vibration and reduces foundation costs. The pulverizer accommodates different requirements through customizable features such as various shapes and constructions for hammers, screens, and liners, available in materials like hardened alloy steel and stainless steel. For finer material, a cyclone with a dust collector can be employed to enhance output. The versatility of this machine extends to applications in spices, chemicals, pigments, coal, agricultural products, animal and poultry feed, providing an adaptable and durable solution for industrial needs.

Mills

Fab-Tech - Industrial Hammer Mill for Pulverizing Various Materials

The Hammer Mill from Fab-tech Engineers is designed for the effective pulverization of materials to 80-100 mesh (150 microns). Constructed with robustness, it serves for the crushing of a wide range of materials including minerals, chemicals, Ayurvedic herbs, and various agricultural products. This mill has a capacity range from 100 to 5000 KG/HR, making it versatile for different industrial applications including pigments, coal, gram, maize, rice husk, sawdust, and animal feeds, among others. It features interchangeable components such as hammers, screens, and liners made from materials like hardened alloy steel and stainless steel, tailored to specific requirements for optimal performance and durability. The mill can be configured with or without a cyclone and dust collector depending on the desired particle size and material fineness.

Crusher

Fab-Tech - Jaw Crusher

Fab-Tech Engineers is a leading manufacturer of Jaw Crushers in Gujarat, India. They offer two variants of jaw crushers: Single toggle and Double toggle. The single toggle jaw crusher is engineered with bearings that utilize grease lubrication, emphasizing simplicity in construction and ease of maintenance, while providing a higher percentage of fines. On the other hand, the double toggle jaw crusher uses forced oil lubrication facilitated by an oil pump and nozzles, resulting in the production of particles with sharp edges and lower fines content. These crushers can handle materials up to 9 on the Moh's scale of hardness, making them suitable for processing stone, coal, various minerals, and ores. The double toggle variety is particularly favored in applications requiring the production of grits for infrastructure projects like roads and railway tracks.

Screen

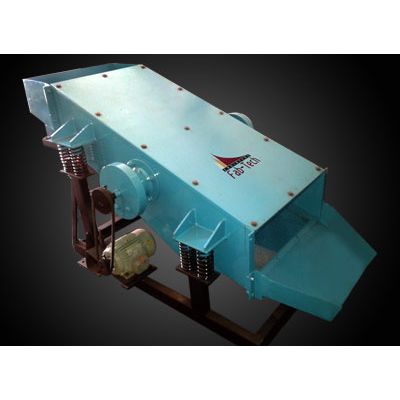

Fab-Tech - Rectangular Vibrating Screen for Material Separation

The rectangular vibrating screen designed by Fab-Tech Engineers is custom-built to meet material separation needs in various industries. The machine is structured using ISMC or IISMA steel sections and heavy-duty MS plates for enhanced durability. Featuring multiple decks, it can be tailored to specific material separation requirements. The machine's main shaft is crafted from En8 material while the springs are made from spring steel, ensuring excellent vibration and extended machinery life. The screens, designed from either MS or SS grade spring steel, are chosen based on client applications. This vibrating screen is highly effective in the quarry, stone, chemical, minerals, food, and agro-product industries.

Other Products

Fab-Tech - Disintegrator Machine for Grinding and Material Handling

The Disintegrator machine by Fab-Tech Engineers is designed to grind materials and discharge them at the bottom, where they can be collected in a bag, drum, or through any conveying system. The machine is available in both mild steel and stainless steel constructions, with a capacity range of up to 10 tons per hour and sizes ranging from 12 inches to 48 inches. The fineness achievable is up to 80 mesh. Optional dust collection systems are available to manage fine dust, and AVM pads can be added to reduce vibrations and save on foundation costs. The machine is versatile and suitable for applications involving coal, chemical, mineral, Ayurvedic herbs, hard and soft materials, and various allied industries. Different shapes and constructions of hammers, screens, and liners, including hardened alloy steel and stainless steel, can be tailored to enhance performance and prolong the life of wear and tear parts. This customization ensures optimal results for diverse material types.