- Home

- Companies

- Fabpro Polymers

- Products

Fabpro Polymers products

Concrete Reinforcing Fibers

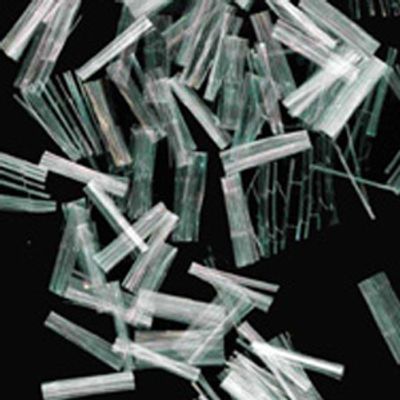

Monofilament Fibers

FABPRO POLYMERS’ SPECTER™ Monofilament Fibers are specially designed to minimize early-age cracking in concrete. Millions of high tensile, high modulus filaments in every yard create an extremely dense, three-dimensional network in most cementitious applications. SPECTER™ Monofilament Fibers have the unique ability to reduce explosive spalling and damage in the event of a fire. SPECTER™ Monofilament Fibers are manufactured from 100% virgin, homopolymer polypropylene resin and meet the requirements of ASTM C1116/C1116M “Standard Specification for Fiber-Reinforced Concrete”, ASTM D7508/D7508M “Standard Specification for Polyolefin Chopped Strands for use in Concrete” and the requirements of ICC ES AC32 Sections 3.1.1 for plastic shrinkage reinforcement.

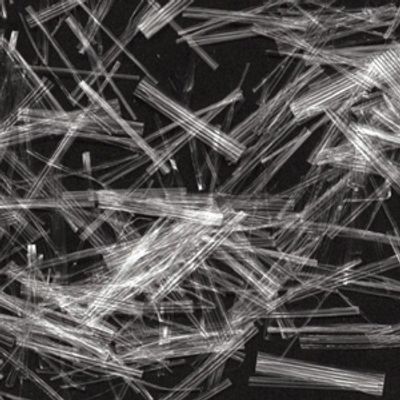

Synthetic Micro Fiber

SPECTER™ 3.5 Synthetic Micro Fiber is a true “Best-in-Class” fiber for reinforcement of concrete. FABPRO’s unique technology combines ultra-thin diameter with ultra-high strength, resulting in the highest level of plastic shrinkage crack reduction at only 0.75 lbs per cubic yard of concrete. Millions of high tensile, high modulus filaments in every yard create an extremely dense, three-dimensional network in most cementitious applications. SPECTER™ 3.5’s superior ability to reduce early age cracking can be accomplished at a minimum dosage as low as 0.50 lbs per cubic yard, with optimum results at the recommended and engineered dosage rate of 0.75 lbs per cubic yard of concrete.

Synthetic Micro Fiber

FABPRO POLYMERS’ SPECTER™ HP Synthetic Micro Fiber is a “Best In Class” new generation of polypropylene microfiber for concrete reinforcement. FABPRO’S unique technology combines ultra thin diameter with high strength, resulting in the highest level of plastic shrinkage crack prevention available. Over a hundred million high tensile and high modulus filaments per yard of SPECTER™ HP create an extremely dense, three-dimensional network in any cementitious application. SPECTER™ HP’s superior ability to reduce early age cracking is accomplished at an engineered dosage rate of only 0.5 lb/yd3. Independent test results have consistently confirmed that 0.5 lb. of SPECTER™ HP consistently produces superior PSCR results as compared with any other monofilament fibers at a typical 1.0 lb/yd3 dosage rate – providing better performance at a significantly reduced in-place cost. Specter™ HP Fibers are manufactured from 100% virgin homopolymer polypropylene resins, and meet the requirements of ASTM C1116/C1116M “Standard Specification for Fiber-Reinforced Concrete” and the requirements of ICC ES AC32 Sections 3.1.1 for plastic shrinkage reinforcement.

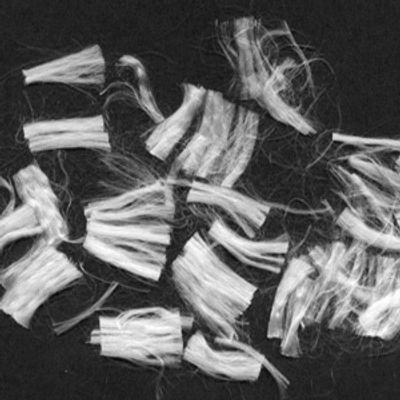

Fibrillated Fibers

GENESIS™ Fibrillated Fibers are designed to provide temperature shrinkage crack control, in addition to plastic shrinkage crack control. GENESIS™ Fibrillated Fibers are manufactured from virgin homopolymer polypropylene resins, and meet the requirements of ASTM C1116/C1116M “Standard Specification for Fiber-Reinforced Concrete”, ASTM D7508/D7508M “Standard Specification for Polyolefin Chopped Strands for use in Concrete”, and the requirements of ICC ES AC32 Section 3.1.1 for plastic shrinkage reinforcement and 3.1.2 for shrinkage and temperature reinforcement. GENESIS™ Fibrillated Fibers are an excellent, cost-effective choice for applications requiring increased residual strength resulting from enhanced mechanical bonding that occurs between the fiber and the mortar mix.

Fibrillated Fibers

GENESIS™ XF Fibrillated Fibers are specially engineered with a patented technology that enhances mechanical bonding with the mortar mix through a micro-reinforcing system. This system improves the residual strength by 26% compared to other leading fibrillated fiber products on the market today. The unique technology of GENESIS™ XF Fibers also provides excellent temperature shrinkage and plastic shrinkage crack control. GENESIS™ XF Fibrillated Fibers are manufactured from virgin homopolymer polypropylene resins, and meet the requirements of ASTM C1116/C1116M “Standard Specification for Fiber-Reinforced Concrete” and the requirements of ICC ES AC32 Section 3.1.1 for plastic shrinkage reinforcement and 3.1.2 for shrinkage and temperature reinforcement.