Fairfield Service Company products

Screening Equipment

Fairfield - Bar Screen

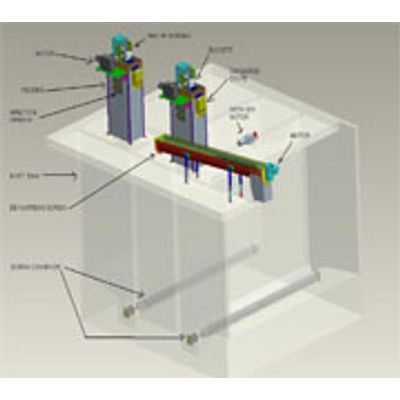

The "MACH" bar screen is a package of mechanical chain operated bar screen previously which is known as CHFF, CHFB & CHFFM. For over last two decades, The "MACH" which is front raked, front/back return bar screen, is the standard for the industry with proven reliability. The "MACH" provides protection for the processing equipments by removing oversize debris from the sewage. Chain operated cleaning rakes intermesh with the bar rack, and elevate collected debris to a discharge point where each rake is wiped off before descending on the return side of the unit.

Fairfield - Bar Screen

The "CLAW" bar screen is a rack and pinion bar screen previously which is known as the "RPFF". From over last many years The "CLAW" which is heavy duty, front clean, front return type travelling rake mechanism transported on climbing carriage, is the standard for the industry with proven quality and reliability. The "CLAW" shall be design to operate in a damp, wet, corrosive atmosphere. The material of construction is depending upon customer requirements and environment operating condition. All parts of the equipment furnished herein shall be amply proportional for continuous operation. Adequate lubrication shall be Provided for bearings, and lubrication points shall be readily accessible.

Grit Collectors

Fairfield - Bucket Elevator

This grit collector consists of a screw conveyor with a vertical bucket elevator and dewatering screw. Grit collector is installed in a regular settling tank designed for a velocity of approximately one foot per second at average sewage flow and sized for not less than one minute retention. Forced air can be introduced into the tank, at period of low sewage flow by means of air diffusers to produce hydraulic turbulence that simulates the normal designed velocity to keep the organic from settling along with the grit.

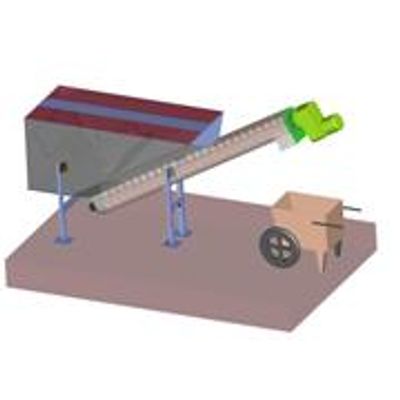

Fairfield - Chain & Bucket/Flight Grit Collector

This grit collector consists of chain and buckets installed in a long narrow horizontal settling channel, dewatering vertical section to elevate the grit from the channel, and screw conveyor to discharge grit into a container or re-circulate the grit back into the channel during periods of maximum flow. This re circulation reduces the organic matter that has settled along with the grit during periods of low sewage flow. This grit collector consists of chain and flights installed in a long narrow horizontal settling channel. It consists a dewatering discharge section inclined 30 degrees from the horizontal designed to discharge the grit into a container or re-circulate it back into the channel.

Fairfield - Grit Classifiers

Grit Clasifiers can be installed at the elevator discharge section to more efficiently remove organice matter from he grit. The dewatering screw consists of a rectangular water-tight tank with an automatic wash water metering device with the inclined screw discharging the washed grid into a container.

Rectangular Clarifiers

Fairfield - Rectangular Clarifiers

The Fairfield Separation process used by FSCI Rectangular clarifier is most commonly used in very large or space constrained municipal and industrial spaces which remove settled as well as suspended solids from liquids. FSCI Rectangular clarifier has ability to handle heavier sludge loads as well as ability to handle high temperature and highly corrosive chemical compounds. Clarifier includes non metallic parts like chain, sprockets and scrappers having long life with minimum weight. These scrappers are driven by the chains on the both end of the tank.

Conveyor

Fairfield - Screw Conveyor and Live Bottom Bins

Fairfield offers various types of screw conveyors, which are efficient in movement of a wide variety of materials in both horizontal and inclined applications. These screw conveyors are made from high quality steel and has various design also. Fairfield`s Screw conveyors capable of moving a vast variety of materials, the material is moved by a rotating screw that pushes or pulls the material along the bottom and sides of the conveyor housing, shearing the material in the radial clearance between the screw and conveyor housing and causing the material to tumble upon itself as the rotating screw`s face tends to lift the material.

Fairfield - Belt Conveyor

The Fairfield belt conveyors are used to transport light to medium weight of loads such as screened material from bar screen. Belt conveyors can be horizontal or inclined (maximum of 28 degrees), designed to convey materials from the loading points to a discharge area. The friction of the belt can fix the items into the right place on the conveyor without some unnecessary bumps. Friction also avoids smooth accumulation; merging and sorting on the belt. This is available in open or fully enclosed type of construction.

Others Products

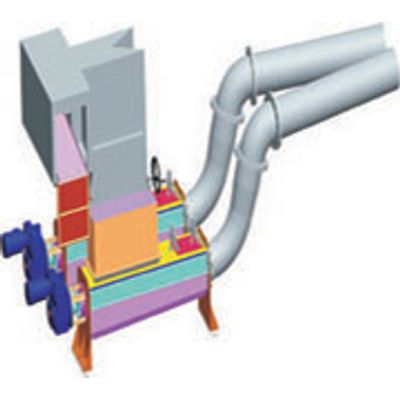

Fairfield - Screw Compactor

The Screw Compactor provided by Fairfield is used to reduce the moisture content, organic content, and volume of screening material coming from the shaft less screw conveyor. Screening material is entering in an inlet hopper, which will include a mechanical divider that will direct the screening to the compactor. From the inlet hopper screening material will be transported by the rotating screw in to the washing zone. In the washing zone wash water is sprayed through the hollow shaft screw in to the screening material, During normal flow condition compactor shall be operated in forward and reverse direction.

Fairfield - Aeration System

The Aerated-Facultative Lagoon process is a natural solution to man made pollution. ADS purifies water the same way nature does. Our systems work like a rolling river, a process that has been going on for thousands of years. ADS can meet all existing or proposed effluent regulation very cost effectively without use of chemicals