FCT – Flow Control Technologies products

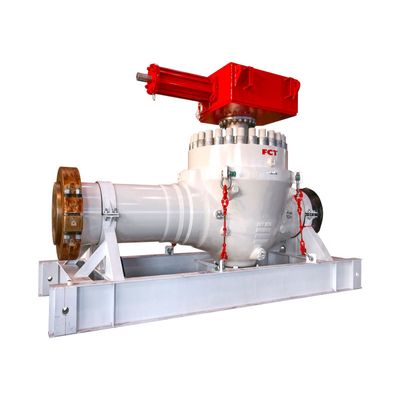

FCT - Top Entry Valve

The Top Entry Valve by FCT is designed for critical service applications in various industries, providing robust and reliable performance. The valve can accommodate sizes ranging from DN 50 to DN 1500 and is applicable under ASME Class 150 – 2500 and API 6A API 3000 – API 20000 standards. It operates efficiently in temperatures ranging from -101°C (subject to international standards and specific requirements) to +400°C. Key features include a trunnion-mounted design, compatibility with various flange types such as RF, RTJ, WE, Hub (clamp), and Compact flanges, and a double block and bleed capability. The valve is SIL 3 compliant, ensuring high safety integrity for severe conditions. The body and trim materials range from carbon steel to exotic materials like stainless steel, duplex, super duplex, 6MO, Alloy 625, Monel, and even titanium. This versatility makes it suitable for a wide array of application requirements.

FCT - Tandem DBB Valve for Double Block and Bleed Applications

The Tandem DBB Valve from FCT is designed for double block and bleed applications, following the specifications of API 6D (type A). This valve is trunnion mounted and allows for double isolation and bleed to ensure operational safety and reliability. The product features various flange options including RF, RTJ, WE, Hub (clamp), and compact flanges, which offer flexibility for different installation requirements. It is compliant with SIL 3 standards, ensuring high safety integrity suitable for critical applications. The body and trim are manufactured from robust materials designed to withstand high pressures and temperature ranges, making it suitable for diverse and demanding environments.