Felco Industries, Ltd. products

Felco - Tamping Pad Roller Compaction Buckets

Felco Roller Compaction Buckets allow an excavator operator to backfill open trench spoils and compact them with one attachment – by combining the compaction performance of Felco’s proven tamping pad wheel compactor within an excavator bucket shell.

Felco - Spike Roller Compaction Buckets

Felco SPIKE Roller Compaction Buckets allow an excavator operator to backfill open trench spoils and compact them with one attachment – by combining the compaction performance of Felco’s proven spike wheel compactor within an excavator bucket shell. The T-1 Steel Spike configuration helps the excavator push the wheel through sticky clay to achieve compaction.

Felco - Straddle Wheel Compactors

Felco Straddle Wheel Compactors are designed to efficiently and uniformly backfill large diameter pipe. Within the rigid exterior frames, Felco uses our proven Sealed Journal Bearing System so the strength of the axle assemblies, combined with their maintenance-free design (no greasing) provides superior performance and less downtime due to its ability to withstand heavy use and is supported by our industry best 5-YEAR LIMITED WARRANTY.

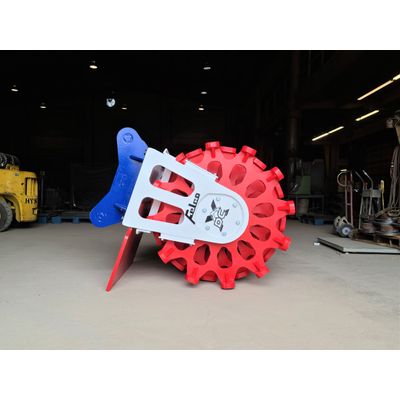

Felco - Segmented Wheel Compactors

Felco Segmented Wheel Compactors combine traditional soil penetrating rims with our proven Sealed Journal Bearing (SJB) System. Protected within our rigid exterior frame, the maintenance-free design (no greasing) provides superior performance and less downtime due to its ability to withstand heavy use and is supported by an industry best FIVE-YEAR LIMITED WARRANTY.

Felco - Spike Wheel Compactors

Felco SPIKE Wheel Compactors feature T-1 steel spikes which help the excavator push the wheel compactor down and through sticky clay material to achieve compaction. Within the rigid exterior frame, Felco uses our proven Sealed Journal Bearing System so the strength of the axle assembly, combined with its maintenance-free design (no greasing) provides superior performance and less downtime due to its ability to withstand heavy use and is backed by an industry best FIVE-YEAR LIMITED WARRANTY.

Felco - Vibratory Plate Compactors

Felco Vibratory Plate Compactors are the ideal tool when it comes to compacting on tight repair jobs, trenches, foundations, or slope applications. Vibratory compaction forces the air in the soils to the surface which decreases air pockets making them ideal for compacting granular materials. These vibratory plate tamper units can apply from 3,500 to 40,000 pounds of impact force depending on size and model. Each compactor vibrates at around 2,100 Cycles Per Minute or Frequency, which has been found to provide optimum compaction for the widest range of granular soils.

Felco - 3-in-1 Vibratory Wheel Compactors

Recognizing the popularity of Trench / Walk Behind Rollers that combine Static and Vibratory Compaction to get that extra few points of compaction, but also hearing the downsides of these units from contractors, Felco is proud to introduce our patent pending 3-in-1 Vibratory Wheel Compactor.

Felco - Mini Excavator Vibratory Compaction Buckets

Felco Mini EX Vibratory Compaction Buckets combine the compaction performance of either a Rammer or NPK Vibratory Plate Compactor with the versatility of a bucket. These vibratory units can apply from 3,500 to 8,000 pounds of impact force depending on size and model. Vibratory compaction forces the air in the soils to the surface which decreases air pockets making them ideal for compacting granular materials.

Felco - Mini Excavator Wheel Compactors

Felco Mini Ex Wheel Compactors have a specially designed wheel assembly to ensure optimal compaction, while featuring greaseable flange bearings instead of our sealed journal bearing to reduce weight for use with mini excavators. Mini Ex Wheel Compactors are a great solution for compacting on tight repair jobs when you need the extra range of a stand-alone wheel. Replaceable scraper teeth on the Tamping Pad Wheels, or dedicated scrapers on the Segmented Wheels, keep material from building between the compaction bumps / wheels. To replace the flange bearings, just unbolt the wheel from the frame.