Fette Compacting products

Continuous Manufacturing

Fette Compacting - Model FE CPS - Continuous Manufacturing System

The FE CPS is a cutting-edge continuous manufacturing system designed to enhance direct compression in tablet production. This innovative system integrates a continuous dosing, blending, and conveying system with an FE55 tablet press, all controlled through a Human Machine Interface (HMI). Its compact design reduces plant footprints to as little as 5x6.5 meters, while maintaining a broad throughput range of 5 to 200 kilograms per hour. The system's advanced features include a three-station rotary press and embedded Process Analytical Technology (ePAT), allowing for real-time monitoring and adjustment of production parameters. The ePAT technology utilizes sophisticated sensors in process units to ensure quality control, enabling quick responses to any fluctuations. Moreover, the TRI.EASY design simplifies operations and reduces learning curves. Enhancing safety and maintainability, the system is dust-tight, features sealed process chambers, and offers easy access for cleaning.Other Products

Fette Compacting - Advanced Tableting Tools and Systems

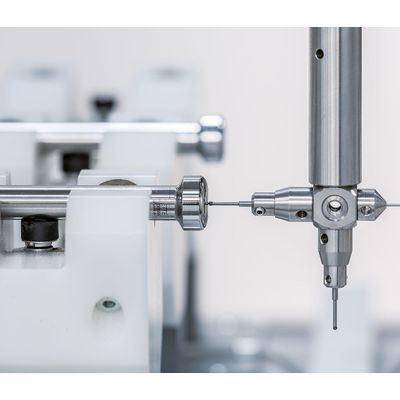

Fette Compacting specializes in developing high-quality tableting tools that ensure optimal performance through their precise compatibility with machines, turrets, and tooling systems. As an expert partner, they provide consultative support to enhance the entire value-added chain for tableting processes. The company offers a diverse range of solutions, including custom FS® punches featuring optimized head shapes for extended service life. Advanced patented segments replace traditional turret die tables, reducing changeover times by 70% and increasing yield volumes. Their Pmax® turrets, combined with FS12® punches, can boost production output by 40% without major investments. The TRI.EASY Tool Box System allows for secure storage, transport, and cleaning of sensitive tools, while the SDC800 cleaning system and PA500 polishing machine optimize tool maintenance. These comprehensive solutions adhere to GMP standards, ensuring efficient operations and durable, reliable performance in various tableting applications.