F.H. Schule Mühlenbau GmbH products

Machines

F-H-Schule - Belt Cooker

In the belt cooker which is shut-off by a feeding and discharge device, the product can be variably treated with steam under overpressure. The product to be treated is fed through the inlet onto a horizontal conveying belt which transports it through the cooker (autoclave) to the discharge device. This ensures particularly gentle treatment of sensitive products. Classical applications of the SCHULE belt cooker include the production of bulgur and instant rice, but it is also used for germ reduction.

FH Schule - Kiln

Both raw oats and oat kernels can be treated using the Schule kiln. Through direct addition of steam between the prebin and the kiln, heat and moisture are introduced into the product before it enters the kiln. As it passes through the kiln, it comes into contact with the so-called heating loops in compartments arranged on top of each other. Depending on the required capacity and temperature, the kiln may consist of 1 - 7 heating compartments. To improve the shelf life, the fat-splitting enzymes are inactivated by indirect steam addition (contact heat). The increase in temperature also has a positive effect on the taste of the product. A specially designed outlet funnel with flow meter regulates the retention time of the product in the kiln and ensures mass flow during product discharge. After hydrothermal treatment in the kiln, the heated product is cooled in a fluidised bed cooler to approx. 10°C above the respective room temperature.

FH Schule - Soaking Tank

The SCHULE soaking tank makes it easy to increase the product moisture. It is made completely of stainless steel, features a conical outlet, and is closed by means of a slide. Above the slide there is a screen insert with a water drain behind it. A water pump ensures constant circulation of the soaking water by pumping the water through the inlet socket at the top of the tank. The water can be additionally heated using a heat exchanger, which can significantly reduce the soaking time. We also offer additional equipment for filling and emptying, cleaning or process monitoring.

F-H-Schule - Counter-Current Coarse Sifter

The SCHULE counter-current coarse sifter is mainly used after shelling or between the pearling passages and sorts out husks, dust, and fine granulate particles. It is used in mills and plants for processing a wide variety of grains, legumes and oilseeds.

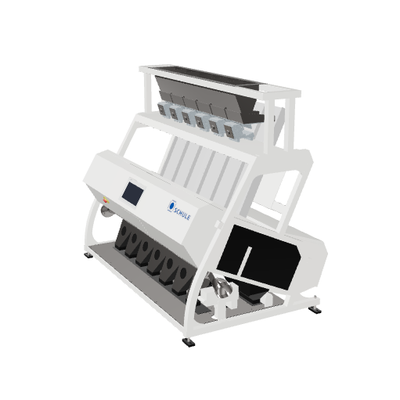

F-H-Schule - Colour Sorting Machine

Colour differences, discolouration, or hidden damage - the colour sorting machine is used where mechanical sorting machines reach their limit.

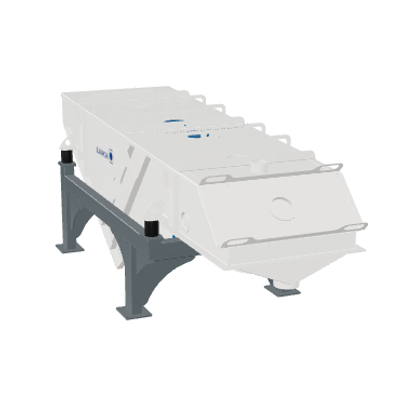

FH Schule - Oat Polisher - Vibration Screen

No matter if you are producing oat, rice, pea or wheat flakes - after flaking and subsequent drying and cooling, the flakes are fed directly into the inlet of the vibration screen. A product distributor in the inlet of the vibration screen spreads the product evenly on the top screen which separates lumps that may have formed. The screened product falls onto the lower screen, where the good product remains and the fines are screened off. All three fractions are discharged via separate outlets.