- Home

- Companies

- Fisher Energy

- Products

Fisher Energy products

Pump Products

Fisher Energy - Multi-Stage Centrifugal Pumps

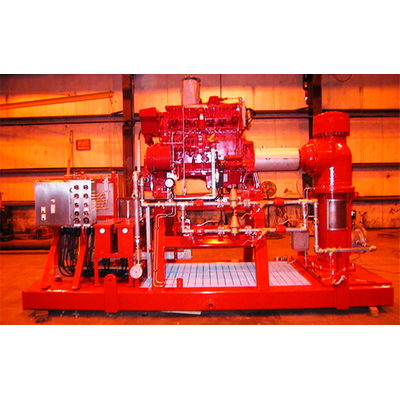

Fisher Energy specializes in designing and delivering advanced pumping solutions tailored to meet international standards such as API-610, ANSI, Hydraulic Institute, and NFPA-20. Their portfolio includes VS-1 Turbine Pumps, Vertical Multi-Stage Turbine Pumps, and Submersible Turbine Pumps, all engineered for reliability and efficiency in demanding applications. The VS-1 Turbine Pumps are robust single casing pumps, available UL listed & FM approved for fire protection. They incorporate innovative features like the FisherPump Single Stuffing box and Spacer Coupling designs for quick seal replacement, and precision flanged, O-ringed columns for positive sealing. The Vertical Multi-Stage Barrel Pump, suitable for high-pressure tasks, is a double casing pump with a suction barrel, ideal for hydrocarbons, LPG, and cryogenic services. Fisher Energy also offers custom-built Submersible Turbine Pumps for offshore applications, featuring simplified assembly with motors directly coupled below the turbine pump assembly. Their experienced engineers provide comprehensive support for configuration, installation, and maintenance, offering replacement parts and repair services for both FisherPump and other brands.Fisher Energy - Pump Systems

Fisher Energy Pump Systems are designed to maximize the efficiency and effectiveness of your operations. Our highly trained engineers configure, install, and maintain pump systems for your most challenging fluid applications. We also provide parts, maintenance, and repair services through the life cycle of your equipment. We offer a number of high performance, low maintenance pumps and systems to meet a variety of pumping conditions and requirements.

Compression Products

Fisher Energy - Air & Inert Gas Compression & Blower Systems

Fisher Energy Air Compressor Systems are designed to optimize your critical pressurized air system for instrumentation, power, and process, with both standard and custom designs. We offer reciprocating, oil flooded rotary screw, oil-free rotary screw, and centrifugal technologies, both electric motor and engine-driven, across a wide range of flow and pressure to meet your requirements. Our custom engineering team specializes in modular packages of complex system including compressors, receivers, dryers, and other auxiliary equipment, including custom controls and instrumentation packages, and systems designed for high pressure and hazardous duty applications. Fisher Energy tests all of it is compressor packages at full operating conditions, prior to shipment, to ensure a quick startup in the field and to confirm performance.

Fisher Energy - Process Gas Compression, Blower & Vacuum Systems

Fisher Energy Process Gas Compression Systems can be found in operation in power plants for natural gas fuel boosting, as sales gas compressors in biogas and landfill gas facilities, pressurizing vent gas for tank farm and unloading facilities, and in various specialized hydrocarbon and process gas applications in chemical and refining processes. Fisher utilizes rotary screw (lube and non-lube), sliding vane, and reciprocating (lube and non-lube) compressors, based on your specific application. These compressors are paired with our engineering know how on modularization and minimization of pulsations and vibrations, and coupled with subsystems for lubrication, acoustics, pressure control, separation, advanced controls and instrumentation, and noise and weather enclosures, dependent on the demands of each application. Fisher Energy maintains a keen focus through the design, fabrication, and start-up phases on operability and maintainability, providing compressor systems with the lowest cost of ownership in the industry.