- Home

- Companies

- Fisher Tank Company

- Services

Fisher Tank Company services

Airports & Military Fueling Facilities

Fisher builds field erected welded steel tanks specifically designed to store Jet-A fuel for airports and military fueling facilities, including foundations and specialized coatings systems. These structures are designed specifically for jet fuel, with epoxy-lined tanks and accessibility for inspection, testing and repair. Special precautions are taken to ensure fuel efficacy and safety. Our customers in the commercial and military fueling space includes Player & Company, POND Engineering, Wharton-Smith, Meccon Industries, Mid Eastern Builders, NOVA, Sierra Construction, and end use facilities including Hartsfield International Airport, the Indianapolis Airport, Charlotte Douglas International Airport, and various military bases and fueling facilities.

Blasting & Coatings Services

Fisher operates full time painting/coating crews ready to support our tank fabrication and construction projects, or to provide field painting/repainting services across the US. We also maintain relationships with fully vetted subcontractors to paint and/or line our tanks when that option makes more sense. This flexibility is just one way we’re able to respond to our customers’ needs and provide the best possible solution.

Pre-Construction Services

Collaboration with customers at this early phase helps all parties understand all the options available and their consequences, and to align expectations. Fisher’s pre-construction services help customers lay the groundwork for a highly successful project. Our experience and insights mean we’re able to see a project from a “big picture” perspective, and to identify even the smallest details that could impact a project. Our contributions help make the design and building process more effective with preliminary technical information, planning and scheduling, and budgetary pricing.

Storage Tank Services

Fisher Tank provides a full range of services, from engineering and design, blasting and coatings, fabrication, and construction, to repairs, modifications, maintenance and field painting. We also provide turnkey services when jobs require start-to-finish project management and construction.

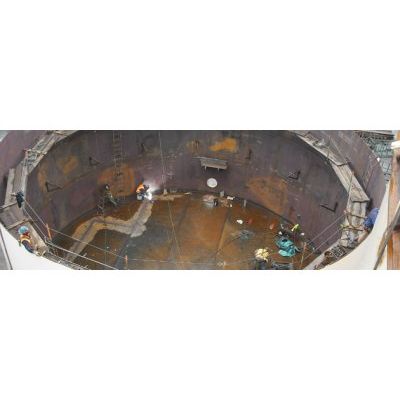

Field Construction Service

Fisher Tank’s field construction methods are state-of-the-art in both process and safety. Our teams are made up of long-term, permanent employees who know tanks inside and out, and are committed to safe, successful projects. Fisher crews have the insights and agility to work with customers and site owners in a way that eliminates disruption to the workflow and helps ensure optimum productivity.

Repairs & Modifications Service

Fisher Tank’s vast experience and knowledge of tank materials, construction and performance enables us to provide skilled repair, modification and maintenance services that help you keep your tanks in top condition, with minimal disruption to your business. All work is performed in accordance with API-653 and ASME standards under the supervision of experienced foremen.

Fabrication Services

The relationships we’ve developed with our suppliers – some going back to our founding in 1948 – allow Fisher to procure the highest quality and best delivery, both of which help ensure schedule commitments. Because we purchase such a high volume of plate materials, we can go direct to mills, eliminating the middle person. The savings to customers is significant. We also carry stock material so that we’re always able to respond quickly to customers’ needs.

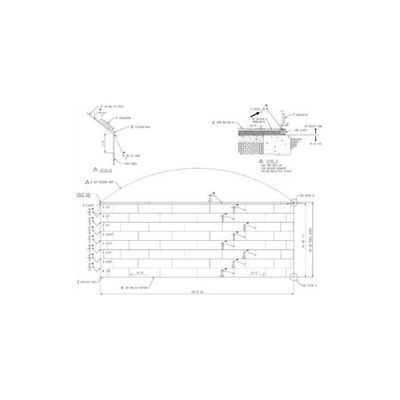

Engineering & Design Services

Complex needs and challenges don’t stand in the way of our engineers and designers. Not only do we take advantage of impressive state-of-the-art technologies, but we’ve also developed more than 50 in-house automated drawing routines that reduce the time it takes to detail by 50%. This efficiency saves customers significant time and money.

Tank Design & Engineering Services

Fisher Tank provides tank design and engineering per API 650, API 620, API 653, AWWA D-100. AWWA Section 14 and NFPA/FM global. Our in-house engineering team works with these standards as well as our clients` drawings to perform custom engineering for each project.

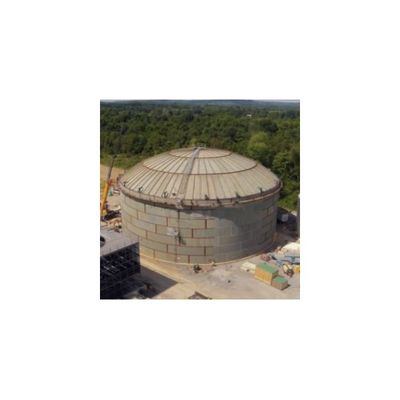

Power

Welded Steel TES Tanks, Storage Tanks, Stacks & Silos

Today’s power generation projects require smart solutions for emissions control, liquid storage, fuel supply, wastewater treatment, coal ash management, thermal energy storage, and plant construction. Fisher Tank Company has the experience, knowledge and qualifications necessary to work safely and effectively in the complex environments of power generation facilities.