Fives I.T.A.S. s.p.a. products

High Precision Machines - Material Removal Solutions -Milling - Vertical Milling - Gantries – Powerful and Multi-Functional

Fives-ITAS - Compact Gantry Mill

The Forest-Liné Modumill Ti is a compact gantry mill designed for the specific needs of titanium processing. Suitable for stand-alone or FMS configuration, this 5-axis vertical mill combined with a moving table, benefits from high stiffness and accuracy thanks to the patented "constant overhang ram".

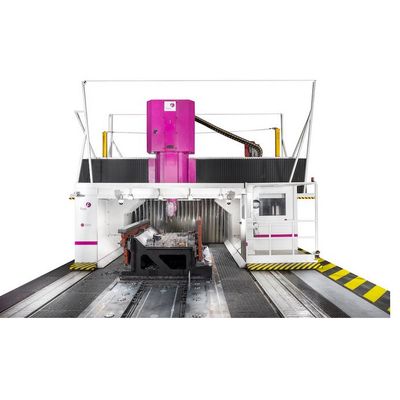

Fives ITAS - Heavy Duty Gantry Mill

The Forest-Liné Modumill is a powerful, robust solution for medium to large capacity machining, providing high accuracy and long-term reliability. Highly stiff, engineered for thermal stability and with optimized damping, precision is a priority in this heavy-duty gantry mill. Furthermore, the high accuracy portal machining center is complemented by a modular design that can be adapted to your requirements.

Fives ITAS - Versatile Bridge Mill With Moving Table

The Liné Machines Vertamill features a moving worktable that allows the spindle to remain in the same position for machining process and viewpoint. The Liné Machines Vertamill features a moving worktable that allows the spindle to remain in the same position for machining process and viewpoint.

Fives ITAS - Compact and Robust Bedtable Gantry Mill

The Liné Machines Gicamill is designed for high-precision machining. With up to 5-axes, it is ideal for machining components up to 2 m high x 2.5 m wide. The one-piece bed/worktable sections ensure optimum accuracy between the spindle and the worktable, while minimising the machine’s footprint.

Fives ITAS - Four-Axis Low Rail Gantry Mill

A four-axis, low rail gantry mill that is specifically designed to handle difficult rail machining applications, such as manganese-steel frogs and switches. The Liné Machines Gicamill R has a robust and compact design comprising a rigid one-piece bed and work table sections that support the gantry. This cost-efficient solution assures optimized load distribution and provides the high performance needed for difficult-to-mill materials.

High Precision Machines - Material Removal Solutions - Turning

Fives ITAS - Model VTC Series - Vertical Turning Machine

The Giddings & Lewis VTC Series, with tables from 1000 mm to 4500 mm, are designed to meet the specific cutting needs of multiple industries, based on feedback from customers. The designs prioritize flexibility, with multifunctional capabilities on a single machine. There are also multiple tooling and attachment options for increased versatility.

Ecology

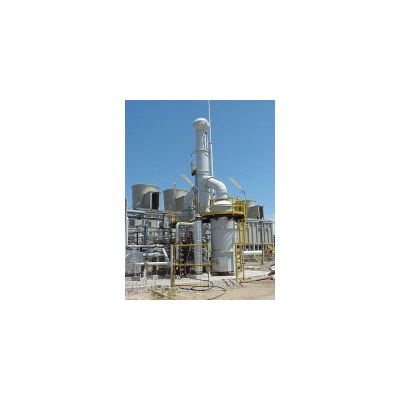

Heat Recuperative Oxidizers

The Heat Recuperative Oxidizers allow the recovery of energy from the combustion of hydrocarbons without generating polluting emissions.

Thermal Catalytic Oxidizers

The oxidizing reactions, that take place in thermal plants at temperature above 700 °C, may be obtained at lower temperatures by means of a catalytic bed consisting of metal oxides or salts of precious metals.

Regenerative Catalytic Oxidizers

The heat regenerative and catalytic oxidizers distinguish themselves from the heat regenerating technology, as the ceramic mass inside the reactors contains the catalysts and therefore the auto-thermal is obtained with low concentrations (0.7 to 1.5 g/Nm3). The use of ceramic masses containing the catalysts allows existing Regenerative type plants to be transformed into Catalytic ones with the advantage of reducing the support gas consumption where low concentrations exist and the auto-thermal point is far away.

Regenerative Thermal Oxidizers

They are installed when there is no need of heat recovery or when this need is not sufficient to justify a heat recuperating oxidizing unit.