- Home

- Companies

- Flame Spray SpA

- Products

Flame Spray SpA products

Technology - Thermal Spray

Flame Spray - Arc Spray Coatings System

Discover the Arc Spray technology, the most effective method for protecting your surfaces from corrosion and restoring worn-out components quickly and affordably. Thanks to a cold process, Arc Spray applies durable metallic coatings without altering the substrate, ensuring long-lasting results on any surface. From rust prevention on steel structures to the regeneration of critical parts, Arc Spray is the ideal choice for various industries. Enhance the longevity of your materials with a coating that truly makes a difference!

Flame Spray - High-Velocity Oxygen Fuel (HVOF) Coating

High-Velocity Oxygen Fuel (HVOF) is an advanced thermal spray process that deposits extremely durable coatings on various materials. It uses a high-speed stream of oxygen and fuel to plasticize and propel powdered coating materials onto surfaces, resulting in exceptionally dense and wear-resistant coatings, ideal for applications requiring protection against wear and hot oxidation.

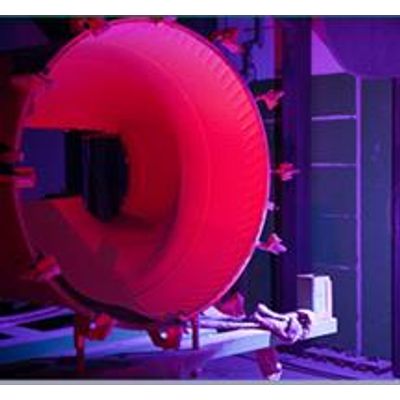

Flame Spray - Air Plasma Spray (APS)

APS is a versatile and highly efficient way to apply protective coatings to various substrates, improving surface properties and extending component life. This method is ideal for a wide range of materials and industrial applications, making it a popular option in industries such as aerospace, automotive, and power generation.

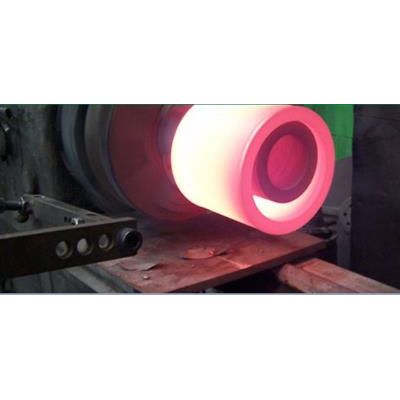

Flame Spray - Spray & Fuse

Spray and Fuse is an innovative process that uses thermal spraying and subsequent heat treatment to improve the resistance and adhesion of the applied coating. This process is particularly suitable for applications requiring superior protection from wear and corrosion.

Flame Spray - Cold Spray System

Cold spray technology is a cutting-edge method for surface coating and repair that uses high-speed particle impact to deposit materials without the need for traditional high-temperature melting. By accelerating solid particles to supersonic speeds, it enables precise and efficient coating applications, offering enhanced material properties, reduced thermal degradation, and expanded possibilities for industries such as aerospace, automotive, and manufacturing.

Flame Spray - Wire Spray Coating

Wire Spray is a cost-effective thermal spray technique used for restoration purposes. By utilizing inexpensive wire feedstock, this process efficiently restores worn or damaged components. It provides an economical solution for extending the lifespan of industrial equipment while maintaining quality and performance.

Technology - Slurry

Flame Spray - Slurry Coating

Slurry Aluminium coating compressor blade protection with its advanced corrosion-resistant properties. Through a meticulously engineered process, a precisely formulated slurry is applied, forming a resilient shield on the blade surface.

Gas Turbines

LT Corrosion

Wet corrosion takes place in environments where the relative humidity is fairly high. The corrosion may cause a uniform destruction or localized destruction (pitting, stress corrosion cracking) of the metal surface. The gas turbine`s axial compressors operate in aggressive environmental conditions where low temperature corrosion phenomena, like wet corrosion, are very frequent. Aluminum based slurry coatings are widely used and approved for protection against these kinds of problems, guaranteeing an excellent galvanic protection to the blades metal.

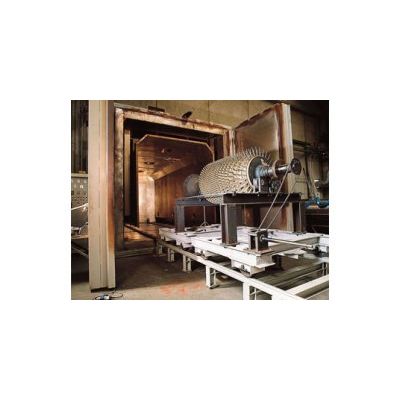

Spraylast - Model 287 - Thermal Load

The Spraylast 287 series includes various types of Yttria Partially Stabilized Zirconia (YPSZ) coatings, all characterized by a very low thermal conductivity. Spraylast™ 287 coatings are the perfect solution where high Thermal loads have to be faced. Gas turbines and other large industrial equipment with high thermal efficiencies contain components or parts that are subjected to immense thermal stress (like thermal fatigue). To contain this stress it is necessary to reduce the surface temperature of the combustion components. An efficient way to achieve this result is to apply a coating with a low thermal conductivity like a ceramic material (Zirconia stabilized Yttria ZrO2 - Y2 O3). These coatings are commonly called Thermal Barrier Coating (TBC) and are applied by means of Atmospheric Plasma Spray (APS).

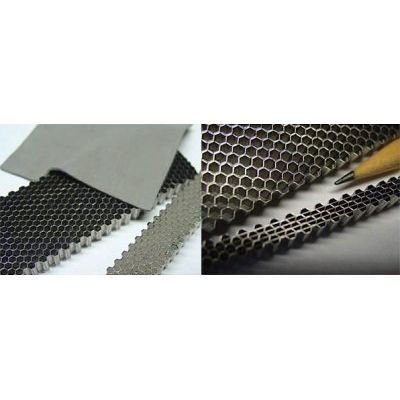

Alloy - Model 100 Series - Sealing Coating

Alloy 100 coating series and honeycomb brazing are the Flame Spray solution to reduce the clearance in rotatory equipment. The efficiency of Gas Turbines can be increased by reducing clearances between the housing and the rotating blades or vane tips in the compressor and in the turbine to minimize or prevent leaks of air or combustion products between the two components. Thus, so called abradable coatings or materials are applied on housing by means of thermal spray techniques like APS or brazing. Different chemistry of abradable materials should be selected according to operating conditions of the involved components.