Flame Spray Technologies BV products

Thermal Spray Systems and Equipment

Turn-Key Systems

FST designs, manufactures and has installed turn-key systems & projects all over the world for different industries and applications. Turn-key coating systems are fully engineered and integrated facilities, designed to offer tailor-made and best practice solutions. Typically, a system includes the core coating and control equipment, and all required peripheral components, such as sound-proof spray booths, robotic handling, turntables, dust collectors. These components are fully integrated for operation in automatic mode. This also allows the user to monitor and control the operational status, and all alarm and e-stop features.

Thermal Spray Systems and Equipment - Thermal Spray Systems - HVOF Thermal Spray Systems

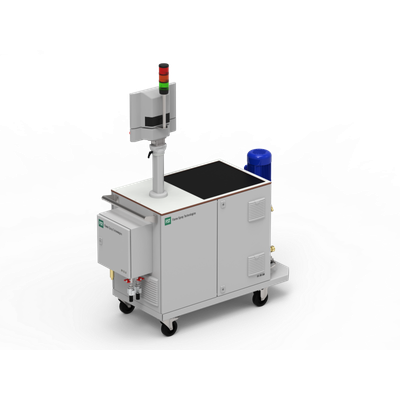

Model HV-50 Digital Series - Hvof System - Liquid Fuel

The HV-50 Digital Series is a stand-alone single process, mass flow controlled (MFC) HVOF coating system. Built using only state-of-the-art components and technologies, the HV-50 is designed to be both reliable and functional and can be used in every type of HVOF application, ranging from R&D, single-piece production to high volume production.FST - Model Hv-50-Lf/M Mobile - Liquid Fuel - HVOF Coating System

The HV-50M/LF is a stand-alone single process, mass flow controlled (MFC) HVOF coating system. Built using only state-of-the-art components and technologies, the HV-50 is designed to be both reliable and functional and can be used in every type of HVOF application, ranging from R&D, single-piece production to high volume production.Auxiliary Equipment

FST - Model FST-10 & FST-20 - Powder Feeders

FST offers the FST-10 (single feeder) and FST-20 (twin feeder). The FST-20 versions can operate two feeding lines separately or simultaneously (dual feeding principle). All FST powder feeders are also available as stand-alone units. Stand-alone feeders can be operated independent from external controller or digitally master / slave integrated via profinet with existing thermal spray or laser cladding systems. The feeding principle is based on the volumetric principle and provides continuous feeding and precise and reproducible powder feed rates. A weight loss option is available allowing for closed loop feed rate control based on material weight in grams per minute. The powder feeders can be equipped with mass flow controllers for accurate and consistent control of the carrier gases.

FST - Gun and Part Manipulation Equipment

FST gun and part manipulation equipment precisely controls the movement of the workpiece and the relative position to the spray torch. All FST equipment is specifically designed to work in the harsh thermal spray environment. Besides a range of standard manipulation equipment, at FST we know that our customers often require custom designed manipulation equipment unique to the specific process requirements and production volume. During a system project our engineers and designers invest time getting to understand your unique needs and requirements so they can develop a truly custom solution. We pour the utmost care and attention to detail into creating designs that meet your specific requirements. Once you approve the design, our manufacturing teams use the final designs to create high-quality, highly durable custom manipulation equipment that will enhance your daily operations.