3 products found

Fluid Energy Processing and Equipment Company products

Fluid Energy - Particle Size Reduction System

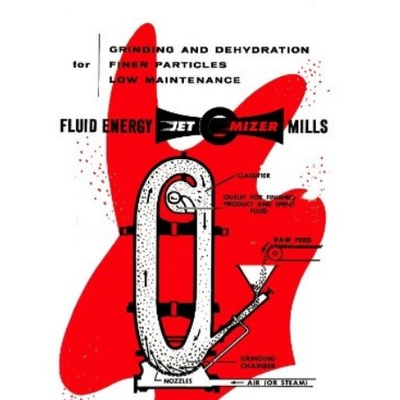

The Jet-O-Mizer is a sophisticated particle size reduction system tailored for fine and ultra-fine powder grinding, managing particle sizes between 0.5 and 45 microns. It operates as a vertically configured jet mill with an inverted trapezoidal chamber design, optimizing particle concentration at the grinding nozzles for enhanced efficiency and reduced wear. This system is particularly beneficial for materials sensitive to heat as the cooling effect of the grinding fluid counteracts any resultant heat. With an adjustable classification zone, it allows precise control over particle size distribution suitable for various products. The robust construction, made entirely in the USA, guarantees high durability and low maintenance, capable of continuous operation all year. Furthermore, Fluide Energy provides comprehensive support, including operational testing to tailor optimal conditions for diverse processing needs, reinforcing the system’s adaptability for combined grinding and secondary processes like drying and blending.

Fluid Energy - Particle Size Reduction System

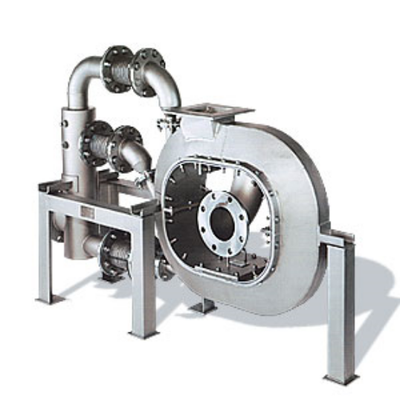

Fluid Energy Processing and Equipment Company offers the Micro-Jet, a horizontal jet mill engineered to meet a broad range of ultra-fine grinding applications. This system is specifically designed to achieve particle sizes averaging between 0.5 and 45 microns, making it highly effective for industries requiring precise particle size control. Utilizing tangential grinding nozzles, the system grinds dry powders while producing maximum surface area with minimal heat impact, thus allowing for the processing of heat-sensitive materials. The Micro-Jet's adaptability is further enhanced with interchangeable grinding nozzles and liners, which are available in various materials such as alumina ceramic and tungsten carbide, tailored for abrasive and contamination-sensitive products. The system offers straightforward cleaning and maintenance, and can combine grinding with additional physical or chemical processes. Capable of operating continuously, and constructed from high-quality components, the Micro-Jet promises efficient and dependable performance.

Fluid Energy - Flash Drying System

The Thermajet Flash Drying System by Fluid Energy is designed for efficient and effective drying and de-agglomeration of various materials, particularly heat-sensitive and reactive products. It offers a combination of flash drying and calcining within a single system, making it versatile for different industrial applications, including handling powders, slurries, and filter cakes. The system utilizes a continuous, dynamic convective hot air process, where turbulent airflow facilitates rapid moisture evaporation and product de-agglomeration without significant temperature elevation, thus maintaining product integrity. Engineered for a wide range of production scales, from laboratory to full-scale output, the Thermajet accommodates various operational conditions, ensuring safe processing across diverse sectors. The system's robust design, constructed entirely in the USA, is low-maintenance with no moving parts, which allows for quick inspection and cleaning. Additional features include closed-loop systems for safe solvent processing and rental options for immediate needs. Comprehensive engineering support and testing are available to optimize and tailor the system's performance to specific requirements.