Fluidyne Corporation products

Wastewater Treatment

Fluidyne - Integrated Surge Anoxic Mix System

The ISAM is a total treatment system incorporating BOD, TSS and nitrogen removal along with sludge reduction in an integrated system. Raw (crude) sewage enters a covered anaerobic reactor for pretreatment, sludge thickening and sludge destruction. Complex organic solids undergo hydrolysis to simpler soluble organics which pass to the surge anoxic mix (SAM) tank.

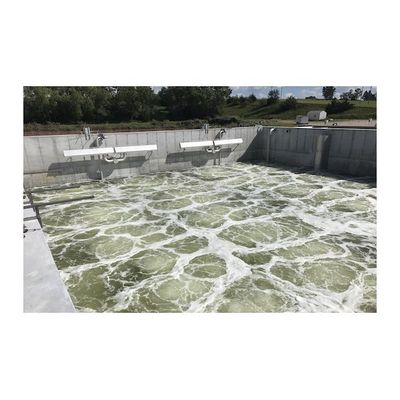

Fluidyne - Surge Anoxic Mix System

Fluidyne was the first company in the US to promote the SAM product. It is at the top of our mainstay reliable products. The newest Fluidyne wastewater treatment systems incorporate a surge/anoxic mix (SAM) tank to control the process and provide rapid and complete treatment. The Surge Anoxic Mix (SAM) System integrates anoxic and aerobic processes for energy efficient BOD, TSS and nutrient removal.

Fluidyne - Wastewater Multi-Channel Orbital System

Fluidyne replaced existing surface rotors and mixers with jet aeration / mixing equipment. The upgrade improves nitrogen and phosphorous removal and increasing the organic and hydraulic loading capability through the process while saving power.

Fluidyne - Sequencing Batch Reactor System

The Fluidyne Sequencing Batch Reactor (SBR) handles all of the work of conventional continuous-flow treatment systems in just one tank. There may be multiple tanks in operation, but that is modular adjustment to capacity needs. All processes - biological, oxidation, sedimentation, nitrification and denitrification occur in a single tank. There is no need for separate aerating and mixing zones or final clarifiers common in other biological processes.

Grit Removal

Fluidyne Hydro-Grit - High Efficiency Grit Vortex System

Fluidyne’s Hydro-Grit grit vortex system removes sand and inorganic material before the wastewater treatment process. Historically one of our most popular and effective products, the high efficiency Hydro-Grit offers the same advantages as the standard Hydro-Grit with improved grit removal efficiencies. Performance data through the high-efficiency unit has shown 95% removal of all grit 74 micron and larger.

Fluidyne Hydro-Grit - Standard Efficiency Vortex Grit Separation System

Using a combination of inlet feed stream energy and auxiliary water jet energy, the Fluidyne Hydro-Grit™ vortex grit separation system is unique in design and the benefits provided, yet the principles of its operation are well-proven. Grit and other heavy particles are separated, washed and removed from liquid streams effectively and efficiently. The Hydro-Grit™ system is all-hydraulic, non-mechanical and non-clogging.

Fluidyne Hydro-Grit - Wastewater Grit Classifier System

The Hydro-Grit Classifier is designed for the separation, dewatering and removal of settleable inorganic material typically at the inlet/headworks of a municipal or industrial wastewater treatment plant.

Sludge Reduction Systems

Fluidyne - Sludge Reduction System

Fluidyne is the first company to commercially design, build and operate SBR technology based on the activated sludge process with over 300 plants operating worldwide. Our intimate process knowledge in biological treatment has led to reducing solid content through biological means. The ISAM sludge reduction system from Fluidyne Can be used as a side stream process in an existing plant to reduce sludge. It incorporates a constant-level anaerobic basin followed by a surge/anoxic/mix (SAM) tank, and an aeration basin that incorporates BOD, TSS and nitrogen removal along with sludge reduction in an integrated system.

Aeration / Mixing

Fluidyne - Wastewater Jet Aeration Systems

Fluidyne Jet Aeration provides an economical and effective approach to oxidizing and mixing wastewater. Jet Aeration Systems are ideal for both industrial and municipal activated sludge processes including SBRs, oxidation ditches, extended aeration and BNR. Due to their flexibility, large solids handling capability and efficiency, jets are also commonly used in aerobic digesters, sludge holding tanks, flow equalization basins and post aeration tanks.

Fluidyne - Wastewater Jet Aspiration System

Jet aspiration is a simple, efficient and cost effective solution to wastewater treatment and mixing problems. Liquid from the tank is pumped through a specially designed double nozzle assembly which aspirates air into the mixing section. The combined air/liquid plume is then discharged below the surface to provide high oxygen transfer and off-bottom solids suspension.