Fluitec - Mixing + Reaction Solutions AG products

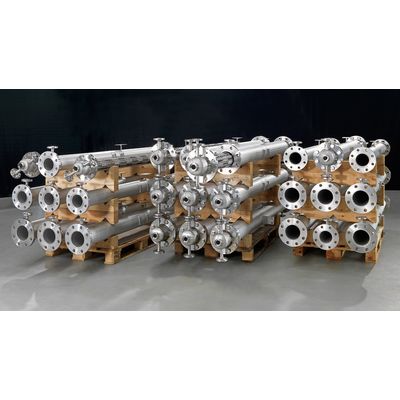

Mixer/Heat Exchanger

Fluitec - Mixer/Heat Exchanger

The design of the mixer / heat exchanger equates to a combination of a static mixer and a multitube heat exchanger in which a highly viscous product on the shell side flows through the static mixer. The advantages of these two distinct systems are aggregated for use at laminar flow.

Systems

Fluitec - Dosing Stations

Dosing technology for static mixers entails controlled, simultaneous and pulsation-free metering of the additive and main streams into a static mixer. As static mixers are generally designed with only minimal back-mixing, the components have to be dosed constantly over time. Fluitec dosing stations were specially developed for problematic media.

Fluitec - DeNOx Systems

The design, manufacture and installation of flue gas mixers – including complete ammonia dosing stations for SCR DeNOx processes (catalytic elimination of NOx) – are among Fluitec`s outstanding strengths. The equilibration of concentration and temperature profiles over the cross-sectional area of the duct channels must be achieved with the smallest possible pressure drop.

In-line Reaction Technology

Fluitec - Contiplant – Continuous Reaction Technology

Owing to the modular design of the Fluitec Contiplant system, it is now an easy matter to test the conversion from batch to continuous reaction processes and assess the economic impact. In many cases, significant business potential can be identified based on the higher concentrations, better temperature control or other process intensification measures. This potential can then be leveraged consistently when moving from the laboratory to the pilot plant due to the excellent heat transfer rate of the Fluitec Contiplant modules. The achievement of full modularity results in a shorter and more straightforward design phase.

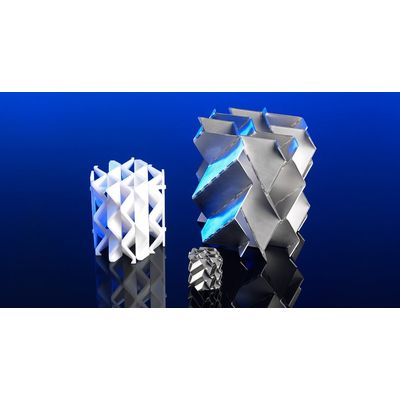

Static Mixing

Fluitec - Laminar Static Mixer

Laminar mixing processes are based on the repeated separation of the flow into layers, followed by redistribution and recombination parallel to the flow direction. The number of layers, and hence the homogeneity, increases with each additional mixing element. The design and length of the mixer vary according to the mixing task. The challenge confronting manufacturers is to offer an efficient, energy saving mixer for every mixing application.

Fluitec - Turbulent Static Mixers

Static mixers can significantly reduce the time required for mixing processes if the flow in the tube is turbulent. Special mixing elements are used here to form the vortex. Mixing and homogenisation take place in the downstream mixer tube. Two mixer designs have proved particularly successful in the last few years: the Aquamix slide-in mixer for installation in existing tubes and the Vortix housing-type mixer, which can be supplied in several different designs and materials (metal or plastic).

Fluitec - Static Mixers for Dispersion, Emulsion and Mass Transfer

Insoluble media can be easily dispersed or contacted with the help of static mixers. Static mixers are ideal for washing, reaction and mass transfer processes. They can be designed and built for both laminar and turbulent flows such that the droplet size, mass transfer surfaces and extraction and emulsion processes can be fine-tuned to the requirements of the process.

Fluitec - Dosing Use of Static Mixers

The use of static mixers in the laminar flow regime makes great demands on the additive dosing technique. The fluid must be guaranteed to exit in a controlled way without pulsation, taking account of the specific properties of the mixer, and clogging must be reliably prevented.