Framo Morat GmbH & Co. KG products

Linear Actuator

Framo Linear actuators are based on the economic minimum principle:The use of powerful coaxial motors enables the required stroke force to be achieved using a minimum amount of space. The Mini is therefore especially useful for operation where space is limited.A wide range of options enables it to be individually adapted for almost any application. There are several customization options.

Gear Technology

Framo - Drive Shafts for Electric Vehicles

Our product range includes rotor shafts, gears with internal and external teeth as well as pinions and chain sprockets that we produce according to individual customer requests for both straight and angled gearing. In this manufacturing stage, we process a variety of materials – steel, aluminum, various non-ferrous metals and plastics – and use their individual properties according to your requirement profile. As a result, we can ensure that you always receive a high-quality product that is tailored to your application.

Worm Gear Sets

Worm Gear Sets

Steel, right-hand threaded worm, case hardened HV 620 – 700. Worm gear made of CuZn37Mn3Al2PbSi or plastic or laminate 2083 upon request. The output torque rating (T2) applies to the initial speed of 2800 rpm at the worm (shaft). The efficiency values (see table in worm gear set catalog) are guidelines. The bearing, lubrication, speed, and installation, in addition to the lead angle, can influence efficiency. Gears may be combined only with worms of the same axial distance and with the same transmission ratio. Worms or worm gears from other manufacturers may not be paired with the counterpiece from Framo Morat. It is almost always necessary to adjust the toothing specifications.

All dimensions can be adapted upon request.

Worm Gear Sets

Steel, right-hand threaded worm, case hardened HV 620 – 700. Worm gear made of CuZn37Mn3Al2PbSi or plastic or laminate 2083 upon request. The output torque rating (T2) applies to the initial speed of 2800 rpm at the worm (shaft). The efficiency values (see table in worm gear set catalog) are guidelines. The bearing, lubrication, speed, and installation, in addition to the lead angle, can influence efficiency. Gears may be combined only with worms of the same axial distance and with the same transmission ratio. Worms or worm gears from other manufacturers may not be paired with the counterpiece from Framo Morat. It is almost always necessary to adjust the toothing specifications.

All dimensions can be adapted upon request.

Worm Gear Sets - Customized Worm Gear Sets

Framo - Customized Worm Gear Sets

Customized worm gear sets are produced in various designs and materials according to customer specifications. Framo Morat supplies customized gear sets in axial distances of 17 to 210 mm at a max. worm gear diameter of 300 mm. If necessary, Framo Morat calculates the toothing data, defines materials and the surface treatment and provides consultation with respect to lubrication and torque loads. For this purpose, there is a calculation program, which is oriented to the DIN standard. Framo’s 40 years of experience in manufacturing worm gear sets showed that our customers rely primarily on existing gear cutting tools, particularly when dealing with short delivery times and low unit quantities. As a result, the procedure must be checked on a case-by-case basis. To do so, you can contact us personally or use the request form.

Framo - Duplex Gearing

The gear variety designed as a duplex worm gear set is especially suited for drives that require positioning at precise angles with high gear ratios. A plus factor is that the gearing backlash can be adjusted repeatedly. If after a longer period of operation the circumferential backlash increases, the gearing can be readjusted so that it is low backlash. For this purpose, the worm shaft is shifted axially in the gear housing by small increments. This is done, for instance, using shim rings when installing the fixed bearing or by means of adjusting screws in the housing cover. The duplex gearing is distinguished by tooth flanks with different helix angles. Axial adjustment of the worm shaft results in low backlash engagement of the worm tooth pitch with the teeth of the worm gear. Worm gear sets by Framo Morat that can be adjusted for low backlash are available from module 0.3 through module 8.

Planetary Gears

Low-Backlash Planetary Gears

The low-backlash planetary gearheads of the GSA series are designed for high positioning accuracy and highly dynamic cycle operation. Ground, helical toothed precision components inside the gear ensure low running noise and high running smoothness. Thanks to its robust design, the gear unit is convincing in applications in which large radial and axial forces are exerted. The hole pattern on the output side allows easy mounting.

Planetary Gears

The GSB line stands for high performance in combination with low backlash and high precision. Helical gears ensure a minimum noise level and smooth running. The robust, one-piece housing improves the gear rigidity and enables the absorption of high loads. The GSB line aligns economic efficiency with flexibility and is your perfect fit for a multitude of applications.

Hub Gears

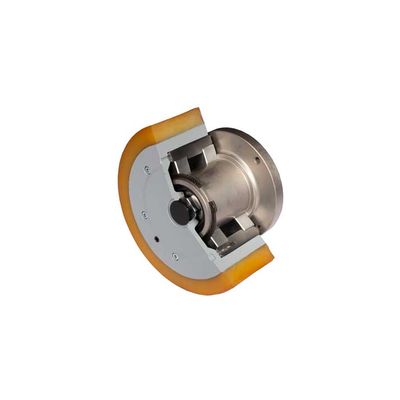

Hub Gear

Hub gears from Framo Morat are suitable for a huge range of application areas, both indoors and outdoors. These applications include high-bay warehouses in the intralogistics field, the transport of medication in hospitals, and automated, future-oriented agriculture. The NG250 drive unit can manage loads of up to 250 kg per wheel. The compact design of the drive unit makes it perfect even when space is at a premium.

Hub Gear

Hub gears from Framo Morat are suitable for a huge range of application areas, both indoors and outdoors. These applications include high-bay warehouses in the intralogistics field, the transport of medication in hospitals, and automated, future-oriented agriculture. The NG500 drive unit can manage loads of up to 500 kg per wheel. The compact design of the drive unit makes it perfect even when space is at a premium.