Freudenberg Performance Materials products

Nonwovens

Drylaid Nonwovens

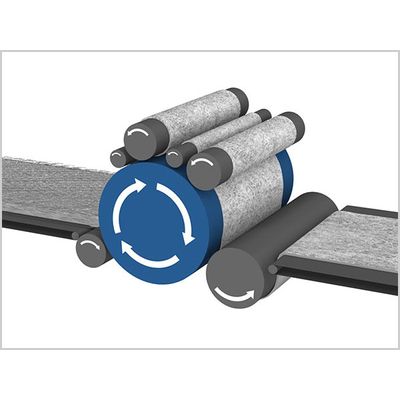

Drylaid nonwovens are made from staple fibers which the nonwoven manufacturers source in. Before processing the fibers are opened and mixed. The web formation takes place on roller cards with rotating workers and strippers. To achieve high fabric weights crosslappers are used. Depending on the application, a large range of fibers can be used, such as synthetic fibers including viscose, natural fibers, glas fibers or carbon fibers.

Spunlaid Nonwovens

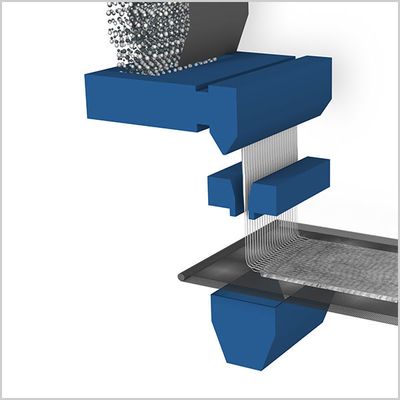

Compared to drylaid nonwowens, the spunlaid technology eliminates the costly transformation of polymers into staple fibers. In this process, synthetic polymers in chip or flake form are extruded. The molten polymers, predominantly Polypropylene, Polyester or Polyethylene, are first spun into endless filaments by spinnerets. Underneath the spinnerets the filaments are cooled and stretched by air and are laid down on an apron in a continuous process. To achieve the required properties of filaments like titer, strength, elongation and shrinkage Polyester needs higher spinning speeds than e. g. Polyolefins.

Knitted Fabrics

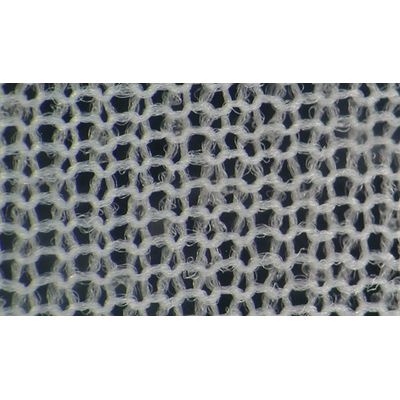

Circular Knit

Circular knit, elastic in all directions. These materials are used in combination with very elastic outer fabrics. Using very fine threads, very light textiles can be produced.