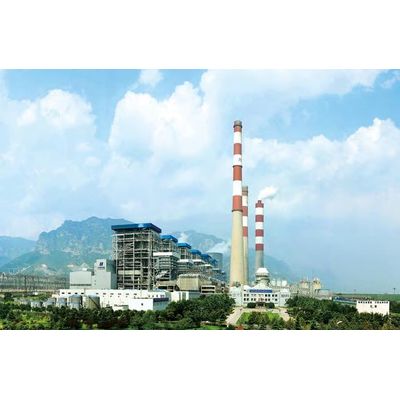

Fujian Longking Co., Ltd products

Dedusting

Longking - Electrostatic Precipitator

Longking supplies comprehensive environmental solutions including conventional type ESP, low-low temperature ESP, Wet ESP,electromechanical two-stage ESP, moving electrode, power-off rapping, non-leakage GGH device etc. The BEH type ESP independently researched and developed by Longking, a combination of advanced technologies and capable to realize the low dust emission requirements,has been applied to more than 750 projects with an installed capacity of more than 300GW. The world`s biggest ESP project—ESPs for 660MW units of Tiroda Power Plant in India. BEH type ESP for 2×1000 MW units of Xuzhou Power Plant

Longking - Low Low Temperature Electrostatic Fabric Precipitator

The low-low temperature ESP initially developed by Longking can realize the multi-pollutant coordination treatment such as particulate matter,SO3, PM2.5, Hg and other pollutants, the collecting efficiency can reach over 98% and save the coal consumption for more than 1.5 g/kWh, and it has been utilized in more than 150 projects with an installed capacity of more than 80000 MW.

Longking - Wet Electrostatic Low Temperature Electrostatic Fabric Precipitator

In 2010, Longking pioneered in developing Wet electrostatic precipitator for power plant in China. This independently developed technology joined Government sponsored 863 research subject, and was utilized in largescale coal-fired units with the capacities of 300MW, 600MW and 1000MW.Test results showed the WBE type Wet ESP with metal plate and type WE type Wet ESP (demister) with electro-conductive FRP plate reserched and developed by Longking is able to realize ultra-low emission of dust below than 5mg/Nm3, and at the meantime an efficient coordinated treatment of PM2.5 and SO3, Liquid Discharge from Stacks (LDS), heavy metal Including mercury and other pollutants.

Longking - Electrostatic-Fabric Integrated Precipitator (EFIP)

Longking electrostatic-fabric integrated precipitators have reched the world leading technological level with many application references. Ultra-clean EFIP technology is able to achieve ultra low emission requirement of elow 5mg/Nm3 alone without Wet ESP. In addition, ultra-clean EFIP has the function of removal of PM2.5, mercury, and SO3. It has three advantages including low emission, low. cost, and low power consumption. It has successfully been adopted in more than 30 sets including 1000MW units. It is one of the best techniques to realize ultra-low emission.

Longking - Dry Ultra-low Emission Control Technology

DSC-M dry ultra-low emission control technology and equipment (DSC-M System) has been developed by Longking based on LJD dry CFB-FGD system. It’s a simple yet reliable and cost-effective system with high operational flexibility, and NOx removal can be realized by combination of SNCR/SCR/COA depending on different flue gas sources. It can realize the flue gas emission of NOX≤50mg/Nm3, SO2≤35mg/Nm3, PM≤5mg/Nm3, SO3≤5mg/Nm3, Hg≤3μg/Nm3, as well as zero Liquid Discharge from Stacks,meeting the ultra-low emission standard of "50355+530". The DSC-M system has been applied in different areas including coalfired power plants, sintering plants, pelletizing plants, FCC, coking system, carbon black plants, electrolytic aluminum industry, glass furnace, and other industries

FGD

Longking - Absorber

The "Three Zones in One" absorber of Longking is an ultra clean coordinated control tower technology with the capability for removing of sulfur dioxide, dust, mist, SO3 and PM2.5. This technology can achieve the following ultra-low emission requirements: SO2 emissions below 35mg/Nm3, dust emissions below 5mg/Nm3, the removal efficiency of SO3 is over 70%. This technology also has comprehensive advantages such as small space demand, water saving, energy saving and low cost. This technology has been used in many ultralow emission projects, such as Jiangsu Ligang coal power plant, Xingtai Guotai coal power plant etc.

Bluk Material Handling

Longking - Pneumatic Conveying Technology

Longking has established an international advanced pneumatic conveying testing facility. A series of pneumatic conveying products, which have been developed with the "material property analysis method", have been applied to many projects including 1000MW units and the project achievements are more than 800 sets.