G.F. Puhl products

Balers

Did you know that there are more than 100 possible baler configurations when you consider cylinder stroke rate, cylinder arrangements, tie options, and feed chute options? Let the experts at G.F. Puhl help you size and install the right baler to meet the needs of your production process now and in the future. Choose new balers from industry leaders or select a baler from our used equipment inventory. Reconditioning service also available.

G.F. Puhl - Blowers and Fans

Rugged and reliable, G.F. Puhl blowers and fans have proven their capabilities on thousands of tough applications. We have over 6,500 in the field and the average lifetime exceeds 20 years! State-of-the art technology and skilled craftsmanship come together in our on-site manufacturing facility where we have the capacity to build blowers and fans from the very small to super-sized. Need a replacement blower in a hurry? Our on-site manufacturing facility and nationwide parts network give you the emergency coverage you demand. Enjoy the industry’s quickest turnaround on replacement blowers and fans—no matter when or where you need them.

Switch Valves

Switch valves direct air-conveyable materials to one of several destinations for material segregation. The experts at G.F. Puhl manufacture switch valves for use in our custom-built trim collection systems and as replacement parts for systems built by G.F. Puhl or other companies. The G.F. Puhl in-line switch valve is a reliable "step-saving" method of directing air conveyable materials to one of several destinations for material segregation. It is available with electric, pneumatic, or manual controls.

Model PTS - Trim Separators

The Puhl Trim Separator (PTS) features a curved screen that is easy to remove and adjustable for various material densities. Use the PTS as a concentrator to add capacity to your system. The Puhl curved screen trim separator is easy to service. For detailed dimensions and specifications for Puhl trim separators, visit our Technical Library.

Shredders

G.F. Puhl sells and installs shredders that provide a quick and efficient way to dispose of a wide variety of paper and corrugated scrap. No matter how demanding your production process, our experts will recommend and install a shredding solution to meet your needs. We sell and install the best shredders you can buy, relying on a partnership with industry leading OEMs. For detailed dimensions and specifications for shredders used in G.F. Puhl trim collection systems, visit our Technical Library.

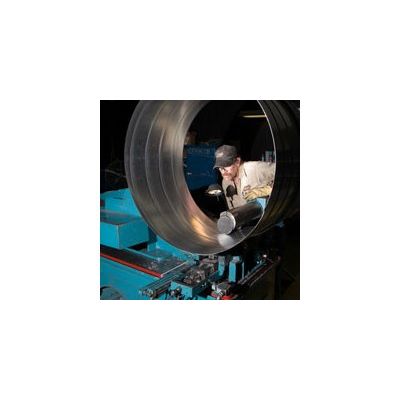

Spiral Duct

Without the network of ductwork and fittings, trim collection systems are nothing more than a collection of spare parts.That’s why G.F. Puhl fabricates our own heavy-duty fittings and spiral duct for your trim system application. We have the ability to produce spiral duct in dimensions from 3` to 60` in our Gallatin, Tennessee manufacturing facility. No matter what you need—ductwork and fittings for a new system or replacement parts for an existing system—our skilled craftsmen can produce what you need with the quick turnaround you expect, even in emergency situations.

Filter Units

Filters do more than just separate dust from the air used to convey it. Filters protect the safety of your employees. That’s why G.F. Puhl filter units are designed to solve a broad range of industrial dust collection problems. Expect continuous service with minimum downtime. Operation is fully automatic with up to 99.9% efficiency. Our engineers understand the safety regulations governing filtering systems and will make sure that your filters are explosion vented to NFPA specifications. G.F. Puhl offers a variety of filtering solutions including reverse air or pulse jet cleaning. Let us help you choose the right one for your trim collection system.

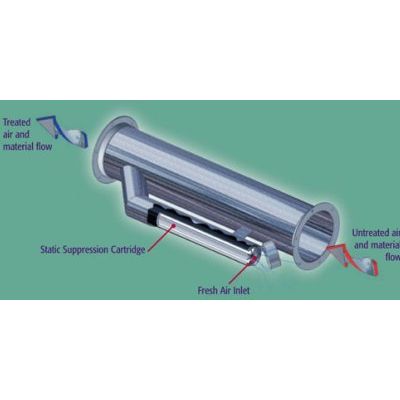

PUHL - Static Suppressors for Trim Collection Systems

Ease of installation, cost efficiency, and no-fuss mechanics make PUHL static suppressors the solution of choice for static problems in your paper trim collection system. When chopped or granulated materials are drawn or blown through ductwork at high speeds, enough friction is created to charge the waste material to high voltages. Once charged, the bits of waste material may stick to each other or cling to the inside of the ductwork and air separator. This quickly clogs the system. Puhl static supressors reduce the static charge and enable materials to move freely through your duct system.