- Plastic Waste Recycling System

- Polymer Technology- Extrusion Systems

- Melt Filtration Screen Changers

- Filtration - Filter Elements

- Measurement Technology - Melt Pressure Transducers

- Film/sheet Applications

- Fiber Applications

- Semi-Finished Products Applications

- Resins Applications

- Recycling Applications

- Filtration Technology - Rotary Filtration Systems

- Measurement Technology – Melt Temperature Sensors

- Amplifier and Digital Display Units

Gneuss Kunststofftechnik GmbH products

Plastic Waste Recycling System

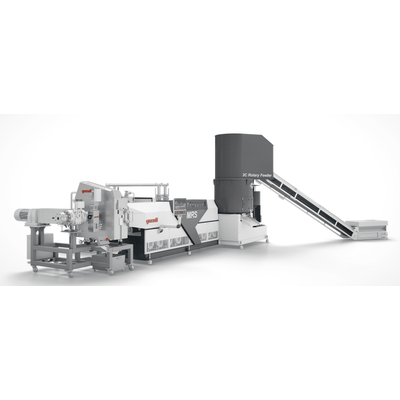

Gneuss - Model OMNI MRS - Polymer Waste Recycling Systems

OMNI recycling systems for the processing of industrial and post-consumer waste from all kinds of polymers.

Polymer Technology- Extrusion Systems

Gneuss - Model MRS - Single-Screw Extruder

Compared to a conventional single-screw extruder, Gneuss’ MRS extrusion system offers many new possibilities for the efficient degassing and recycling of polymer melts. In addition, with the MRS extruder gases or fillers can be homogeneously introduced into the melt.

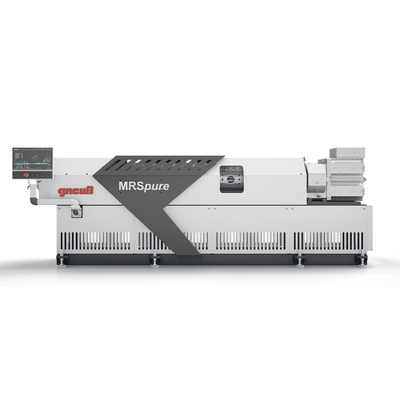

Gneuss - Model MRSpure - Plastic Recycling Extruder

The MRSpure extruder is an extrusion system by Gneuss based on the technology of the MRS extruder (Multi-Rotation-System), but it separates the melting process from the degassing process. With the MRS technology, the polymer melt is delivered into a large single screw drum. The drum contains several small extruder barrels, parallel to the main screw axis. Installed in these small extruder barrels are the satellite screws, which are driven by a ring gear in the main barrel. The satellite screws rotate in the opposite direction to the main screw while they rotate around the screw axis. This increases the surface exchange of the melt disproportionately. This unique MRS technology enables extremly efficient and gentle decontamination of heavily contaminated materials without pre-drying and thus even offers compliance with global food contact standards. The Control System is used to monitor and control the desired values.

Gneuss - Model MDS - Plastic Recycling Extruder

The new and patented MDS extruder from Gneuss is used for a variety of recycling applications. It is characterized by changing diameters of the screw and barrel, as well as a new type of interaction between energy input and degassing. Thanks to its robust design, the MDS is particularly suitable for recycling applications. The highly efficient degassing enables the production of outstanding qualities when processing PET, PA, PLA, but also and especially polyolefins such as HDPE or LDPE. With high-viscous polymers, gentle treatment at low shear rates is important, as high shear rates can destroy the long molecular chains. The multidimensional screw diameter enables optimum melting performance and degassing results while operating with low shear rates. These target values can be monitored using the Gneuss control system.

Melt Filtration Screen Changers

Gneuss - Fully-Automatic Screen Changer

With regard to achievable product quality, economic efficiency and in terms of operator and maintenance friendliness, the RSFgenius offers unrivalled possibilities. This fully-automatic and pressure-constant filtration system can be used in virtually any application, for automation of the production process and for the manufacture of a high quality final product. The RSFgenius is particularly well suited for ultra-fine filtration, the filtration of thermally-sensitive melts and the filtration of materials with a high contamination level.

Gneuss - Model SFXmagnus Series - Screen Changer

With the hydraulic screen changers HSprimus and HSSprimus sturdy screen changers are available, which represent major technical advances combined with operator friendliness and permanent availability. HSprimus and HSSprimus are also available as diverter valves.

Gneuss - Model SFneos Series - Rotary Filter

Patented Rotary Filter with simple and safe handling, suitable for a wide range of applications. The Rotary Filters of the SFneos series are one of Gneuss’ patented rotary filtration systems and operate continuously, with constant process and pressure. They can be used for almost all applications and are characterized by their compact design as well as simple and safe handling. Several screens can be changed at the same time during a screen change process. Screen changes do not have any impact on the product quality.

Gneuss - Model KSF Series - Continuous Process Filtration System

The process-constant and automated filtration system for individual, bespoke solutions in a variety of demanding applications. The KSF screen changer is a continuous, process constant and automatic screen changer which differs from all its Gneuss siblings in that the rotary disc is equipped with circular cavities. These have removable breaker plates as standard.

Gneuß - Model CSFprimus Series - Rotary Filtration System

Patented Rotary Filtration System with large active screen area and two working positions. Patented rotary filtration system with large active screen area and two working positions. The filter disc is divided into two zones, which can be alternately moved into the melt channel. On request (e.g. for batch or roll changes) the positions and thus all screens in the melt channel are automatically changed. The melt flow is not interrupted, so that downstream components do not have to be restarted afterwards. Filter elements can be replaced at any time between two changes.

Filtration - Filter Elements

Gneuss - Plastic Melt Filtration

Highest quality demands on filtered plastic melts can only be met if filtration systems and filter elements are matched to each other based on expert knowledge. The use of Gneuss filter elements ensures consistently high melt and product purity.