- Home

- Companies

- Graham Corporation

- Products

Graham Corporation products

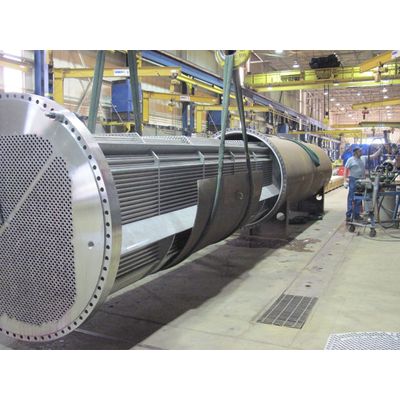

Graham - Process Vacuum Condensers

A properly designed Graham Condenser between the process and vacuum producing equipment will yield significant advantages. The use of a process vacuum condenser can permit significant reduction in the size of the vacuum producing equipment. A condenser can recover for reuse valuable product that’s carried from the process with non-condensable gases. It can reduce the amount of wastes produced by the vacuum system and lower the process operating cost. Graham Process Condensers can be designed for a wide variety installations: direct contact or surface type, mounted horizontally or vertically, freeze condensation or conventional condensation type.

Graham - Liquid Ring Vacuum Pump

Graham liquid ring vacuum pumps are efficient and easy to maintain because there is only one rotating part. Our pumps are robust and can be started and stopped repeatedly, being fit to handle unexpected process upsets, including liquid in the suction, without damage. The exhaust gas stream is oil-free and low temperature. Graham Liquid Ring Pumps can be fabricated in any material to meet the requirements of the process gas. In addition to operating to very deep vacuum levels, our Liquid Ring Pumps can also operate above atmospheric pressure to provide a very wide range of operation. While liquid ring pumps typically operate with water as the service liquid, Graham Pumps can operate with any liquid that is available.

Graham - Steam Jet Ejectors

Steam Jet Ejectors – the largest vacuum producing devices available – are used in the most demanding of applications. Virtually maintenance-free with no moving parts, they can be fabricated from almost any material, and can be used in every industry that requires vacuum. Ejectors can be designed to operate without steam as their pressurized (motive) source. In addition to operating well into the micron HgA range, they can also operate well above atmospheric pressure.