- Home

- Companies

- G.T.S. Grinding Srl

- Products

G.T.S. Grinding Srl products

GTS - Model MG Series - Classifier Mills

The grinding in MG Series classifier mills takes place by high peripheral impact with fixed grinding tools in a circuit closed by a dynamic classifier. Unlike crushing grinding systems, MG classifier mills can be fed by both grits with a maximum diameter of 15 mm and sands with a diameter of 100 μ. This allows feeding with products of a rough pre-grinding.

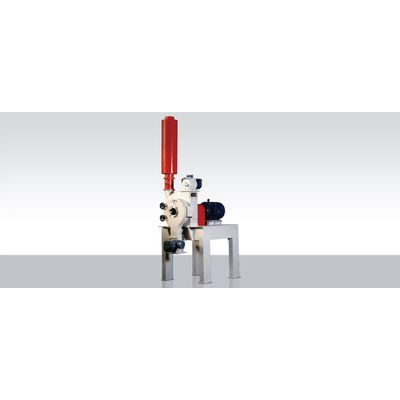

GTS - Model MG-B Series - Classifier Mills

The bestseller version of the classifier mill for flue gas treatment and micronization of Sodium Bicarbonate and Trona. The grinding in MG-B Series classifier mills takes place by high peripheral impact with fixed grinding tools in a circuit closed by a dynamic classifier. At the entrance of the grinding chamber, the material to be processed is immediately sucked by the airflow and parts already sufficiently fine are delivered to injection point thereby reducing the workload of the milling.

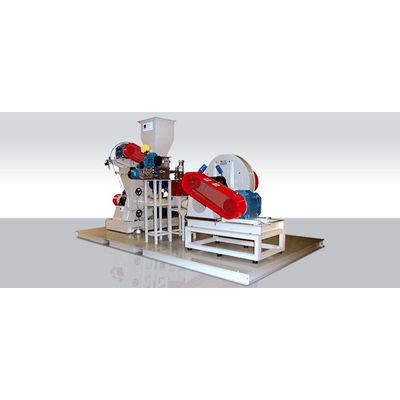

GTS - Model MG P Series - Classifier Mill Grinding Systems

The MG P classifier mill is a patented model specifically developed for the micronization of sodium salts used in the process for the neutralization of emissions in the atmosphere.The MG P classifier mill uses an uncrossed fan which does not require to stop the machine for its cleaning. There is no necessity for the stops, too often delayed for too long and therefore causing malfunctioning, typical of other mills.

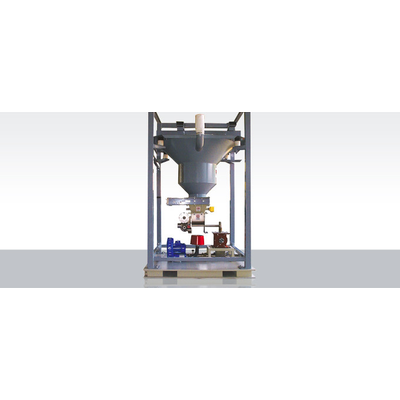

GTS - Model MGS Series - Compact Micronizer Machine

The MGS Micronizer is a mill model purpose-developed for a micronization which does not require an extreme control of the top-cut or which just requires the reduction of previously ground or fine materials. It is a particularly compact machine which is supplied preinstalled on its own easy-to-anchor bed. The extraction and the handling of the micronized product does not require the use of fans for short distances (about 15-20 m). The efficiency of micronization of MGS mills does not require the presence of the classifier and it compensates its absence. The particular characteristics are the reduced dimensions, the low power installed and the absence of a fan for the handling of the micronized product thanks to the airflow produced by the micronizer itself.

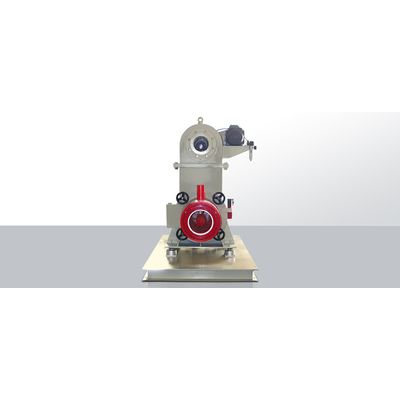

GTS - Model MS 370 - Microclassifier Machine

MS 370 microclassifier is a machine for the classification of fine products, with a minimum top cut of 5 µm, present in already ground powders products. The classifier is of the fixed cage dynamic type. The classification of the particles is carried out by applying contrary forces on them, this way causing the separation of granules according to their diameter. The feeding dosage takes place by a screw controlled by a processing regulator which keeps the consumption of the main motors within a highly efficient range. The introduction of the material in the microclassifier takes place by a rotary valve.

GTS - Activated Carbon

In some industrial and burning systems furans and dioxines can be produced under certain thermal conditions. Moreover, volatile metals may also be present in some treatments and they can be found in fumes and must all be reduced within the imposed limits of emission imposed due to their toxicity. The activated carbon and the lignite coke assure the reduction requested by the emission limits when they are injected in the fume flux at temperature lower than 200 °C.