- Home

- Companies

- Guardian Couplings

- Products

Guardian Couplings products

Flywheel Couplings

Guardian Couplings - Flywheel Coupling

The FL is a two-piece flywheel coupling used on off-highway construction equipment such as skid steer loaders, aerial lifts, excavators, and many other mobile hydraulic applications. The FL product is our oldest line, and has decades of proven success in the field. Not only is the FL our oldest product line, it is our most economical design! The design consists of a glass reinforced nylon flywheel flange that will fit both SAE and metric flywheels. The mating hub is produced from sintered steel and can be used on both splined and straight shafts. The FL product is considered a torsionally stiff design, and does not require lubrication. This design is interchangeable with other popular coupling brands.

Guardian Couplings - Flywheel Coupling

Guardian has introduced the DELTA Series flexible coupling line for use on diesel-driven hydrostatic machinery and construction equipment. The cost effective DELTA single-piece design incorporates a splined and hardened steel hub that is pre-assembled into the glass-fiber reinforced flange. The DELTA coupling attaches to the engine flywheel, taking advantage of elastomeric grommets that provide a steady dampening effect to normal engine vibrations. Although the coupling incorporates rubber bushings for dampening, it is relatively stiff which allows equipment with low inertia to operate below the critical speed range.

Guardian Couplings - Flywheel Coupling

The FBA coupling is a one piece, all steel drive coupling. The flywheel coupling attaches to the engine flywheel for easy installation. It takes advantage of the elastomeric grommets that provide a steady dampening effect to normal engine vibrations, and helps minimize any side loading to the pump shaft. The FBA provides an easy installation. There is no positioning of hubs to worry about. Simply plug the hydraulic pump into one of our mounting plates or housings, and the pump assembly can be blind fitted into the coupling hub. Pump spline lubrication is required with this design. The FBA coupling is intended to be used with spline shafts only in hydraulic pump applications. The coupling will fit standard SAE flywheels, but is also versatile enough to fit non-standard SAE flywheel designs. Guardian offers this coupling from stock, and can be used on applications up to 450HP.

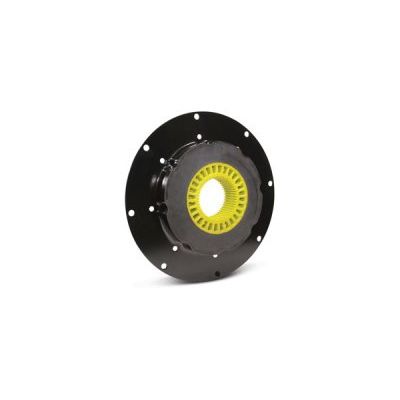

Guardian Couplings - Flywheel Coupling

Guardian has introduced the NV Series flexible coupling line for use on diesel-driven and hydrostatic machinery to provide maximum vibration dampening from a torsionally soft coupling. The NV features a single-piece design that incorporates a cast iron hub, and a steel back plate with molded rubber. The coupling acts as a mechanical fuse and provides protection and dampening for lower driven inertias.

Guardian Couplings - Flywheel Coupling

The Guard-Flex is a torsionally soft, vibration dampening coupling that has an in-shear design. Along with excellent vibration dampening the coupling will offer protection to both the engine and driven equipment when higher inertias are present. The coupling acts as a mechanical fuse, in the event of an overload condition. The coupling is designed to fail through the rubber and shear. Three elastomers are available from stock to provide the proper dampening and stiffness required for your application.

General Purpose Couplings

Guardian Couplings - Curved Jaw Couplings

The Curved Jaw couplings can be utilized in many applications and serve as an all-purpose coupling. The basic design of the Curved Jaw allows for a higher torque capacity in a compact design. The curved tooth has a greater contact area which gives it the high torque capacity, and reduces edge pressure. It will accommodate axial, radial and angular shaft misalignments. The hubs are produced from a variety of materials including; aluminum, gray iron, steel, sintered steel, and stainless steel. The spider elements are available in various durometer options in Urethane & Hytrel. The spiders can perform under normal duty cycle conditions to heavy duty cycles which include shock loading and can minimize torsional vibrations in the system.

Guardian Couplings - Gear Grip Flexible Shaft Couplings

A general use coupling that is best suited for applications with a large degree of misalignment up to 50 HP. The Gear Grip Coupling is a three-piece highly flexible design which includes two hubs and a flexible sleeve. Guardian offers three different sleeve materials including neoprene, urethane, and reinforced neoprene. Depending on the series, the hubs are typically offered in zinc or sintered steel.

GUARDEX - Flexible Shaft Drive Couplings

GUARDEXTM is a double cardanic curved-tooth gear coupling. This three-piece design is able to compensate for axial, radial, and angular shaft misalignment. The coupling consists of a nylon sleeve and two steel hubs. As a result, creates a maintenance free product and doesn’t require any further lubrication. It fits electric motor driven applications up to 300HP. They are perfectly interchangeable with other popular European designs.

Guardian Couplings - Flexible Straight Jaw Couplings

The LJW coupling is a basic industry standard jaw coupling, and is completely interchangeable with other popular brands. Guardian offers the LJW as a standard in steel and cast iron, but if required can also be produced from other materials. Three spider material types are available: Buna-N, Urethane, and Hytrel. The LJW is a very economical solution and will accommodate axial, radial and angular shaft misalignments. Guardian also offers a change-in-place spider design to minimize changeover time.