- Home

- Companies

- Hager Elsässer GmbH

- Products

Hager Elsässer GmbH products

Chemical-Physical Process Technology

H+E FLOCOMAT - Optimised Sedimentation Process

FLOCOMAT®.T is an optimised sedimentation process which ensures reliable solids removal and efficient sludge thickening featuring internal contact sludge recirculation, resulting in a smaller footprint and reduced chemical consumption.

H+E FLOCOPAC - Flocculation and Precipitation Reactor

In industrial process water and wastewater treatment it is often necessary to remove soluble substances that have poor separation properties. Although not very cost- and space effective, the process of flocculation and precipitation has been shown to work reliably for exactly this purpose.

H+E FLOTTOPAC - Air Flotation Unit for Purifying Wastewater

H+E’s brand name FLOTTOPAC® refers to a space saving method that is highly effective in the removal of oils, fats and finely suspended solids in industrial wastewater from various industries and production processes. Therefore, the FLOTTOPAC® can be used in the food and beverage industry as well as in the oil and gas and the paper industry.

Biological-Anaerobic Process Technology

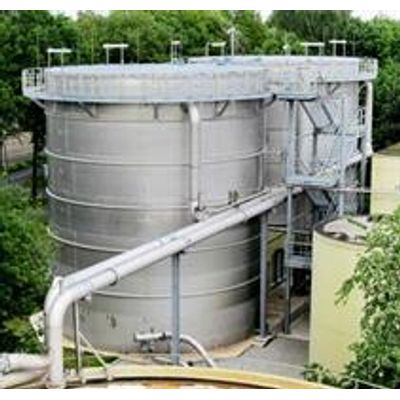

H+E - Biological-Anaerobic Process

H+E’s anaerobic processes are very commonly used in the food & beverage industry and pulp & paper industries. Microbiological processes that take place in the absence of oxygen provide safe conversion of harmful or interfering substances to organic acids and subsequently to simple compounds such as methane or carbon dioxide.

H+E ANAFIT - Expanded Granular Sludge Bed Digestion (EGSB)

The manufacturing processes in the food industry often provide stringent process technology and engineering requirements for the necessary wastewater treatment plants. In many cases the only possible solutions are individually developed and use specifically matched processes.

Biological Aerob Process Technology

H+E BIOFIT - Advanced Oxidation Process (AOP)

With BIOFIT Oxyd2, H+E introduces a new yet already proven method to reliably remove residues in wastewater from industrial production processes that are difficult or impossible to remove using conventional biological processes.

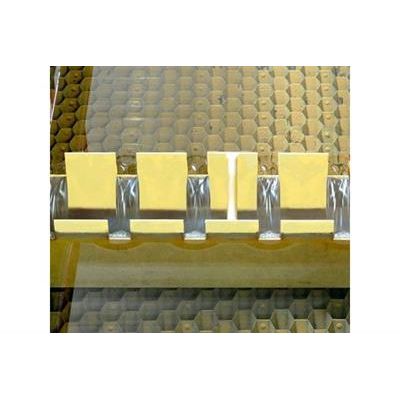

H+E BIOFIT - Up-flow Biological Filter

A versatile biological alternative; From semiconductor manufacture to the petrochemical industry, a wide variety of industrial sectors require the most efficient methods for the purification of low to moderately loaded wastewaters. The separation of solids is required, as is the elimination of carbon or nutrients. Due to its extraordinary adaptability in all kinds of applications, BIOFIT.F provides a truly versatile alternative to the traditional activated sludge process. Following the initial separation of solids, it handles the complete aerobic biological waste water treatment process prior to discharge into the receiving water course. BIOFIT.F uses the parallel flow principle of liquid and vapour phase in a procedurally and operationally superior manner.

H+E BIOFIT - MBBR - Moving Bed Biofilm Reactor

Proven and powerful for maximum loads. BIOFIT.H is a well-proven, robust moving bed process for the biological pre-treatment of highly contaminated wastewater, especially from the paper industry, if anaerobic treatment is not an option. This process is also recommended for other sources of highly polluted wastewater such as those produced in the petrochemical and food industries.

BIOFIT - Combined Nitrification and Denitrification Plant for Wastewater Treatment in Industry

Especially in the production of food and beverages, as well as in the oil and gas industry, wastewaters contain medium to high nitrogen loads. BIOFIT.N is a proven process for nitrogen removal from treated wastewaters. BIOFIT.N is used if nitrogen is existent in wastewater in the form of ammonia, organically bound nitrogen or nitrate, which is the case e.g. in the cleaning and manufacturing processes in the food industry. The BIOFIT.N process achieves this exceptionally high rate of nitrogen removal through its procedural structure. Constructional separation of the nitrification and denitrification process steps increases the efficiency, so that highest removal rates of over 90% can be achieved. At the same time, BIOFIT®.N can be used as an individual process stage or in combination with an upstream selector without additional anaerobic stage.

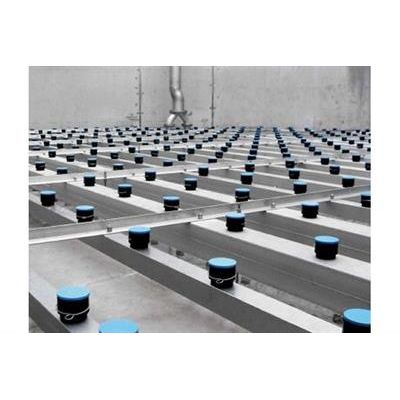

AEROFIT - Medium-size Bubble Aeration System

Energy-efficient. Maintenance-free. Self-cleaning. AEROFIT.V is one of four processes for aeration of waste water within the portfolio of HAGER + ELSÄSSER. Each process has been developed for specific areas of application, each with their own typical characteristics and requirements. For AEROFIT.V, these are mainly for pulp and paper production, the oil and gas industry, and food and beverage production.