Hangzhou Xcellent Composites Limited products

Weaving - Composite Materials

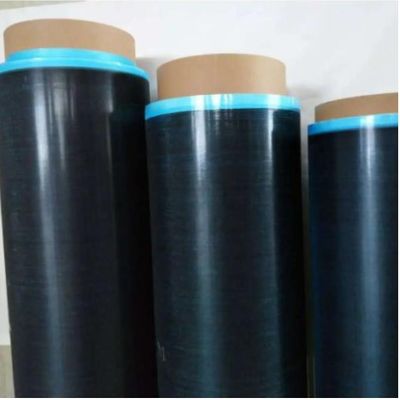

Xcellent - Prepreg Carbon Fiber Woven

Carbon fiber woven prepreg is made by impregnating carbon fiber fabric with a polymer resin matrix. It combines the resin matrix with the fiber reinforcement. Prepreg is not only an intermediate material for processing various composites but can also be directly used to manufacture a wide range of composite components. The quality of the prepreg directly affects the final quality of various composite products. Xcellent also offers hybrid woven prepreg, including carbon kevlar hybrid woven prepreg, carbon fiberglass hybrid woven prepreg, and carbon UHMWPE woven prepreg.

Xcellent - Model UD - Prepreg Carbon Fiber Woven

Carbon fiber UD prepreg is made by impregnating unidirectionally arranged carbon fibers with a high polymer resin matrix. It combines a resin matrix with fiber reinforcement. Xcellent offers UD prepreg with fiber weights ranging from 20 to 600 g/m2 and resin content uniformity controlled within 0.5%. Both fiber weight and resin content can be customized to meet client specifications. Carbon fiber UD prepreg is a primary intermediate material for manufacturing composite structural components. Compared to carbon fiber woven prepreg, it is not only easier to use and allows for precise control of fiber and resin content, but it can also be structurally designed to meet load-bearing requirements, achieving superior structural performance.

Xcellent - Carbon Fiber Rope & Cord

Carbon fiber braided rope or cord is a lightweight and high-strength rope made from the high-performance properties of carbon fiber. This rope is tightly woven from multiple strands of carbon fiber yarn, combining the high tensile strength, excellent fatigue resistance, and extremely low elongation of carbon fiber. Carbon fiber rope possesses excellent dimensional stability and chemical corrosion resistance, maintaining its performance even in harsh environments. The application range of carbon fiber braided rope is extensive, commonly found in aerospace, marine engineering, sports equipment, industrial lifting, and special vehicles. In these applications, they serve as both structural load-bearing components and for shock absorption, suspension, or towing.

Braiding - Composite Materials

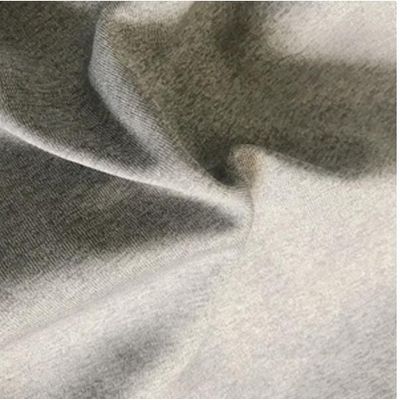

Xcellent - Basalt Fiber Warp Knitting Fabric

Basalt fiber warp knitting fabrics are made by basalt fiber untwisted yarn with polyester yarn. Due to their structure, these fabrics exhibit excellent mechanical properties and quasi-isotropic performance. Common types of warp knitted fabrics include warpwise stitched fabrics, biaxial fabrics, triaxial fabrics, and quadriaxial fabrics. Basalt fiber multiaxial fabric is created by arranging untwisted yarns at 0° and 90° or +45° and -45°, combined with a layer of short-cut fiber filament, or sandwiching a layer of PP in between two layers, and then stitched together using polyester filament. The basalt fiber multiaxial fabric supplied by Xcellent Composites is produced using internationally advanced multiaxial warp knitting equipment and techniques. The composite materials made from basalt fiber multiaxial fabric significantly enhance both the elastic modulus and strength.

Xcellent - Basalt Fiber Mat

Xcellent Composites produces a range of basalt fiber mats, including chopped strand mats, needled mats, and surface mats made from basalt fibers. Basalt fiber chopped strand mat is made by cutting continuous basalt fiber filaments into 50mm lengths, which are uniformly distributed on a forming conveyor belt. After applying an adhesive, the material is dried to form a roll. Basalt fibers are known for their excellent electrical insulation, wave transmission and absorption properties, and high elastic modulus, making them ideal for manufacturing high-performance automotive and marine components. Basalt fiber needled mat is produced by carding basalt fibers and then using a needling or hydro-entanglement process. This creates a non-oriented three-dimensional microporous structure.

Knitting - Composite Materials

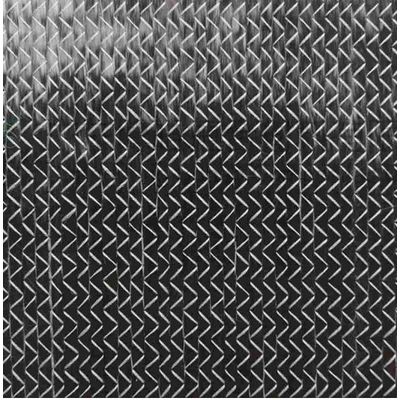

Xcellent - Model UHMWPE - Woven Fabric

UHMWPE woven fabric, crafted from ultra-high molecular weight polyethylene fibers, is a high-performance textile produced using sophisticated weaving technologies. This fabric retains the excellent physical properties of UHMWPE fibers and can be customized through various weaving techniques and finishing processes to meet specific performance needs, such as enhanced tear resistance, flexibility, or improved texture. Xcellent Composites offers UHMWPE woven fabric in a range of densities including 200D, 400D, 600D. 800D, 1000D. 1500D, and 3000D. Available weave patterns include plain, twill, and hybrid weave. These fabrics are ideal for integration with resins and particularly suited for composite material applications.

Prepregging - Composite Materials

Xcellent - Ceramic Fiber Fabric

Ceramic fiber fabric is a high-performance, high-temperature-resistant product made from ceramic fiber yarn. This fabric boasts excellent resistance to high temperatures and chemicals, making it suitable for a variety of extreme environments. Xcellent Composites offers two types of ceramic fiber fabrics based on temperature resistance needs: a standard type (resistant up to 1260°C) and a zirconium-containing type (resistant up to 1430°C). Additionally, to enhance the functionality and application range of the product, the company also provides specially treated products such as aluminum foil-coated ceramic fiber fabric, vermiculite-coated ceramic fiber fabric, and PTFE solution-coated ceramic fiber fabric.