- Home

- Companies

- Hansol EME

- Products

Hansol EME products

Paper Plant

Hansol - Industrial Paper

Mainly manufacturing coated duplex board, highest quality of goods packaging paper, Daejeon Factory of Hansol Paper is equipped with production capacity over 550,000 tons annually. This industrial paper plant was constructed by Hansol EME through state-of- the- art facilities and serves as one of the best industrial paper plants. Based on these performances, Hansol EME completed construction of coated duplex board plant with scale of 60,000 tons annually in Suez, Egypt in 2005 and with scales of 150,000 tons annually in Obeikan, Saudi Arabia in 2006.

Hansol - Special paper

Mainly manufacturing special paper, information paper and fancy paper, the domestic largest scaled Cheonan Factory of Hansol Paper is equipped with production capacity over 120,000 tons annually. Additionally, Sangju Factory is specialized in high value added functional special coated papers such as thermal paper, adhesive memo paper, inkjet paper for photograph. Hansol EME constructed these two plants based on the expertise we have developed for a long period on plant E. P. C and played a crucial role in special paper business sector.

Environment Plant

Hansol - Waste Treatment

We realized a better and bigger dream with eco-friendly solutions. We realized a better and bigger dream with eco-friendly solutions. Hansol EME quickly and safely carries out all processes, from waste collection to transport and recycling, intermediate process to final process, and is taking the lead in establishing clear and clean areas. We are confident in the area of waste treatment, thanks to our many years of experience. Hansol EME independently developed the Waste FBC Sludge Incineration System and constructed Korea’s largest incinerator (700 tons/day). We have rich experience in the design, construction and operation of incineration and dry facilities, both at home and abroad.

Hansol - Waste-to-Resource

Hansol EME is environment plant expert firm by creating values out of waste. Hansol EME produces RDF from daily waste and makes resources out of sewage sludge and food waste. This is one of the core technologies that Hansol wishes to is establishing.

Water & Wastewater Plant

Hansol - Water Treatment

Water treatment is a process of purifying river or underground water so that it will be potable. This is different from the purification of raindrops, domestic water or industrial water into clean water. This is the reason why the water treatment process is more complicated. Suspended matter in source water is settled down in the grit chamber, and source water is mixed with cohesive agents with a flash mixing device, and then coagulated substance in cohesive sediment devices is sunk by clarifier and then is dehydrated at belt filter. Clean water at the top made from clarifier is filtered using a Duhamel media filter before arriving at the purifying plant and being made into drinking water with chemical treatment.

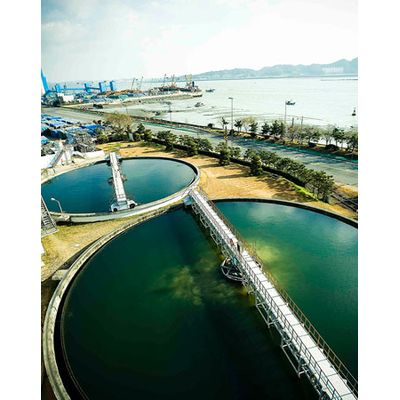

Hansol - Advanced Sewage Treatment (sewage)

We have applied our waste water treatment experience into design/installation/commissioning/operation of an advanced sewage treatment facility and realized optimized sewage treatment. Furthermore, this advanced sewage treatment facility is recognized our competence in removing organics, nitrogen and phosphate. Related technologies include A/O, A2/O, Bardenpho process, SBR methods.

Hansol - Organic Wastewater Energy Recovery

Disposal of food waste and livestock excretions are prohibited in 2012 Ocean Disposal Convention and the government is trying to find how to make organic waste water and turn waste into resource. Hansol EME provides optimized solution with our technology and expertise (Know-how).

Hansol - Sewage –Wastewater Reuse

The Ministry of Environment has stipulated waterworks law to introduce reclaiming water to be used for river maintainance, water head and toilet purpose and recently initiated to supply waste and sewage water for industrial water. We are responding actively to government initiatives and customer requirements on the basis of our technology learned from clean water/ultra-pure facility.