Haynes Equipment Co Inc products

Grinder Pumps

Haynes Equipment Company is the exclusive representative for Environment One Grinder pumps in Kansas, Western Missouri and now at the Lake of the Ozarks and surrounding communities. The E/One Sewer system is a pressure sewer system that is powered by E/One grinder pumps. A pressure sewer system uses small-diameter pipes and grinder pumps, which are often installed at each home. The grinder pump station collects all of the wastewater from the home and grinds it into slurry. The wastewater is then pumped to a larger sewer main or directly to a wastewater treatment plant.

Sewage Lift Stations

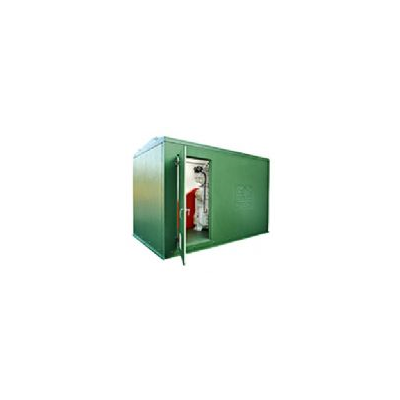

Package Reliasource Pumping Systems

Haynes Equipment Company proudly represents the Gorman Rupp ReliaSource® lift stations which include above- and below-ground pumping stations as well as above-ground submersible valve packages (ASVP) that are 100% custom-engineered, manufactured, assembled and pretested by the experts at Gorman-Rupp. Gorman-Rupp developed the ReliaSource line of complete packaged lift stations to eliminate costly service interruptions that result from inferior lift station components.

Self Priming Pumps/Lift Stations

The term self-priming pump describes a centrifugal pump that uses only it’s rotating assembly to reach a fully-primed pumping condition.A centrifugal pump is any pump that uses centrifugal force to create a pressure differential in a fluid, thus resulting in pumping action. Air is the main enemy of a standard (non-self-priming) centrifugal pump. When the standard centrifugal pump encounters air, it can become air-bound. It`s much harder to pump air than to pump water, so when the air `binds` the pump, the pump can no longer force the water out. When this air-binding happens, the pump is stuck. It won`t operate until the air can be removed in some way. A self-priming centrifugal pump overcomes the problem of air binding by mixing air with water to create a fluid with pumping properties much like those of regular water. The pump then gets rid of the air and moves water only, just like a standard centrifugal pump.

Chemical Feed

Chemical Feed Scales

Haynes Equipment Company has partnered with Force Flow to bring you superior monitoring and controlled chemical feed at your water treatment plant or in your industrial process in Kansas and Western Missouri. Force Flow provides weight-based and ultrasonic systems for monitoring chemical usage, level and feed rate. Also automated onsite chemical dilution and day tank auto refill systems are available.. Take a look to see how Force Flow monitoring and control products can improve your liquid, gas and dry chemical feed applications.

Chlorine Feed

Chlorine (Cl2) is one of the most common liquefied gases used in the disinfection of water and wastewater. Over the past century it has played a vital role in the reduction of disease worldwide. With the development of effective safety products such as scrubbers, automatic tank shutoff systems and all vacuum chlorine gas systems. gas chlorination continues to be an effective treatment method proven to be safe, reliable and very economically priced to meet varying application needs. Haynes Equipment Company has partnered with Chemical Injection Technology to bring you the `Superior” line of products. Chemical Injection Technology is the industry leader in water and wastewater disinfection and treatment providing disinfection systems custom designed to fit your specific needs.

Wastewater Specialty Pumps

Chopper Pump

A chopper pump is a centrifugal pump, which is equipped with a cutting system to facilitate chopping/maceration of solids that are present in the pumped liquid. The main advantage of this type of pump is that it prevents clogging of the pump itself and of the adjacent piping, as all the solids and stringy materials are macerated by the chopping system. Chopper pumps exist in various configurations, including submersible and dry-installed design and they are typically equipped with an electric motor to run the impeller and to provide torque for the chopping system. Due to its high solids handling capabilities, the chopper pump is often used for pumping sewage, sludge, manure slurries, and other liquids that contain large or tough solids.

Grit Pump

Grit is highly abrasive. For wastewater treatment plants, grit is typically defined as an `inorganic solid” and it can be made up of sand, gravel, cinder, glass and other heavy inorganic material. The major abrading component of grit is silica sand. The amount of grit entering these plants varies. However, both facilities must remove it as soon as possible to alleviate erosive wear as the process water moves through the plant for treatment. Grit removal systems are provided in many different forms, and all require pumps for disposal of the inorganic solids. Historically the design choice for grit removal has been the recessed impeller, vortex centrifugal pump or hardened materials for a self-primer pump. These designs have been used in grit/slurry applications for more than 30 years and are industry proven.