- Home

- Companies

- HB-Therm AG

- Products

HB-Therm AG products

HB-Therm - Temperature Control Units for Plastic Injection Molding

Injection molding of plastics requires controlled mold temperatures. Temperature control devices regulate this with a liquid heat transfer medium by supplying or dissipating heat in a controlled manner. Thermo-5 devices are characterized by efficient and reliable operation and are used in the temperature control of injection molding tools or similar processes.

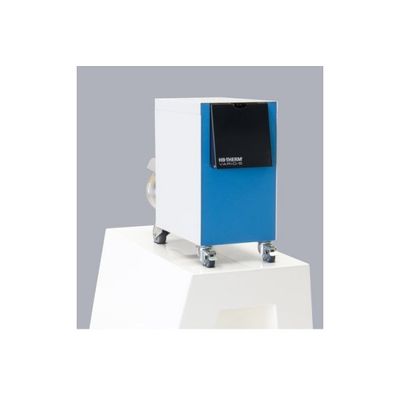

HB-Therm - Switching Unit for Variothermal Temperature Control

Special challenges in injection molding processing can no longer be mastered with conventional temperature control. The solution is variothermal temperature control: high temperature during injection, cold temperature in the cooling phase. Together with two Thermo-5 temperature control units, the Vario-5 switching unit forms a variothermal system based on the fluid-fluid process. It alternately connects the hot and the cold device with the same temperature control circuit. With a suitable arrangement of the temperature control channels, existing tools can also be used. The Vario-5 is characterized by simple and quiet operation. It supports the user in determining the optimum setting.

HB-Therm - Ultrasound Flow Meter for Parallel Circuits

With parallel circuits, there is a risk that changes in the flow will go undetected, since the media flow is divided between the other channels. The external Flow-5 flow meters monitor media circuits connected in parallel and detect changes at an early stage before rejects occur. The Flow-5 are characterized by simple operation and the highly accurate measuring method with ultrasound.

HB-Therm - Water Treatment Unit for Industrial Temperature Control

Unsuitable water in the temperature control circuit leads to calcification and corrosion and thus to increased maintenance costs and early failures. This applies in particular to water temperatures above 140 °C, rotary unions or small temperature control channel cross-sections. The Treat-5 supplies controlled quality system water to temperature control units. It is characterized by simple and ecological operation. The Treat-5 operates automatically once the conditioner has been added and periodically prompts the user to check.

HB-Therm - Cleaning Device

In addition to reduced flow, contamination leads to a deterioration in heat transfer and thus to a reduction in performance. The Clean-5 removes corrosion and calcification in tools, temperature control units and lines and offers extended protection during storage. It is characterized by simple and ecological operation. The Clean-5 prompts the user to add the required amount of funds and then continues to work independently.

HB-Therm - Temperature Control Units

The technology of the Thermo-6 temperature control devices is based on the extremely successful Thermo-5 device series. With over 100,000 devices in use, HB-Therm has become the global market leader. Device technology has always been geared towards quality and durability. HB-Therm proves this with a lifetime guarantee on the core heating components and now also on the flow measurement. "Just better" stands for the consistent further development of our technology.

HB-Therm - Temperature Control Units with Ethernet Interface for Injection Molding

The Thermo-6 temperature control units are equipped with an Ethernet interface as standard and communicate with the injection molding machine or other downstream systems via OPC UA. In combination with a Gate-6 interface server, completely new possibilities arise for the user. The "e-cockpit" Android app sends analysis data to HB-Therm Service at the touch of a button and enables remote access to a device by an HB-Therm specialist. In addition, a device can be remotely controlled via the app and access can be granted to any person. When developing our digital solutions, we naturally paid attention to compliance with the highest security standards.

HB-Therm - Test Device for Temperature Control Devices

Consistent quality and safety in the production process require documented maintenance of all quality-related equipment. This is also one of the requirements of a quality management system. The temperature control unit saves the values obtained using the test device. For analysis and creation of a certificate, the data can be transferred to the PC via a USB stick and further processed using the VIP software.