Headworks International products

Mechanical Equipment

Headworks - Perforator Screen

The Headworks® Perforator design provides increased capture rates with fine openings. The Perforator is a “Perforated-Plate Screen” with perforated elements that form a continuous band which face perpendicular to the channel. Screenings are captured by the elements and are lifted to the discharge point where they are removed by the Dual-Surge™ spray header system. The material is discharged into a sluice trough, conveyor, and/or screenings washer/compactor. The Headworks® Perforator Screen design facilitates ease of installation and dependable operation. The perforated plate screen incorporates sieve elements that are mounted on chains on both sides of the self-contained frame. This arrangement allows for screenings to form a mat. Our philosophy of manufacturing the most robust Bar Screen in the industry influenced the design of the Perforator Screen.TurboWash - Screenings Washer

The TurboWash agitator creates a highly turbulent mixing regiment zone in a channel or tank (similar to the water around a propeller on a motor boat), immediately preceding the screening equipment. Wastewater enters the agitation zone and is heavily mixed. The turbulent zone of influence created by the TurboWash agitator loosens and emulsifies the organic BOD material attached to the screenings allowing the soluble and fine particulate BOD material to pass through the screen openings. Additionally, the screenings device intermittently runs backward, thus pushing retained solids back into the turbulent zones, exposing them to further turbulent actions in order to dislodge the biological particles.

Transporter Shaftless Spiral Conveyor

The Transporter shaftless spiral conveyor is perfect for conveying screenings. An alloy steel shaftless spiral rests in a polyethylene-lined stainless steel trough. Solids are fed directly into the unit and the shaftless spiral conveys the screenings through the transport section. An optional wash zone can be provided, where a flow of wash water removes organics. Transporters can sit at inclines up to 25 degrees and supplied in lengths up to 50 feet. The Transporter shaftless spiral conveyor/compactor can accept screenings from multiple screens.TurboDrum - Inclined In-Channel Water Drum Screen

The TurboDrum IN is installed in a channel at a 35 degree angle. For pressure feed applications, the same unit can also be installed as a self-contained TurboTank system. The operation cycle controlled by monitoring differential head loss across the screen is performed by rotating the basket with the process flow entering the internal diameter of the screen and exiting through the screen elements to the outside. The screenings are retained on the internal surface of the screen by paddles fixed longitudinally to the inner screen surface which carries the material to the top where it is sprayed and falls into the receiving hopper. The receiving hopper spiral conveys the screenings material through the optional washing and compaction zone and discharge outlet.

Spiralman Plus - In-Channel Screen

The Headworks® Spiralman in-channel screen is a shaftless spiral screen that combines screenings, conveying and compacting in a single reliable unit. As the shaftless spiral rotates, it clears screenings from the perforated sieve and conveys them out of the channel. The Spiral is fitted with a brush in the Sieve Zone to keep the screen clean. The solids continue through the Transport Zone, through the optional Wash Zone and ultimately to the Dewatering Zone prior to discharge. To make maintenance both accessible and easy, the entire length of the shaftless spiral screen sits in a U-trough. The Spiral remains the same diameter over its entire length, reducing the potential for blocking. The spiral in the Sieve Zone is bolted to the transport spiral and can easily be removed for brush replacement in a safe and comfortable environment.TurboTank - Stand-Alone Washing Unit

The TurboTank is the stand-alone version of the TurboWash which includes the TurboWash and Spiralman screen, suitable for large volume screenings washing, ie: flow through a sluice trough.

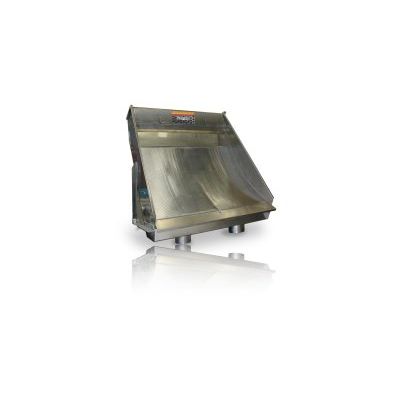

TurboStat - Sidehill Static Screen

The TurboStat sidehill static screen is one of the simplest and most economical methods for solids separation. All units feature a stainless steel wedge wire filtration surface. The working principle is based on a liquid current circulating over the screen`s curved surface. This surface, made up of long triangular metal bars (wedgewire), provides a sequence of edges for cutting the flow, allowing the free liquid to drain through the reduced slot openings while retaining the screened solids at the base of the screen.

TurboDrum - Horizontal Drum Screen

The Headworks Turbudrum IH horizontal drum screen is a unique, in-channel, rotary screen suitable for fine screening of sewage and industrial effluent. It is the ideal solution for large applications requiring fine screens with openings as fine as 1mm and no carryover. This equipment is available in a wide range of hydraulic and separation capacities to allow customizing for the most effective solution for your application.

Biological Process

Integrated Treatment System

Headworks Integrated Treatment (HIT) System The world’s MBBR/IFAS technology experts at Headworks BIO have developed a smarter way to treat wastewater for reuse. The result is the Headworks Integrated Treatment (HIT) System: a modular, compact wastewater treatment system designed for smaller communities and industries. The HIT System provides a complete solution – screening, grit removal, MBBR or IFAS treatment, clarification, tertiary filtration, and disinfection – all with low capital investment and operational costs.

Moving Bed Biofilm Reactor (MBBR)

Moving Bed Biofilm Reactor (MBBR) processes improve reliability, simplify operation, and require less space than traditional wastewater treatment systems. MBBR technology employs thousands of polyethylene biofilm carriers operating in mixed motion within an aerated wastewater treatment basin. Each individual biocarrier increases productivity through providing protected surface area to support the growth of heterotrophic and autotrophic bacteria within its cells. It is this high-density population of bacteria that achieves high-rate biodegradation within the system, while also offering process reliability and ease of operation. This technology provides cost-effective treatment with minimal maintenance since MBBR processes self-maintain an optimum level of productive biofilm. Additionally, the biofilm attached to the mobile biocarriers within the system automatically responds to load fluctuations.