- Home

- Companies

- Herhof GmbH

- Products

Herhof GmbH products

Technologies

Herhof - Separation and Sorting Technology

Apart from the concept and implementation of a complete system for the processing of household waste, we offer you tailor-made systems for waste separation and sorting. This area of operations combines conveyor and shredding systems; separation units according to the specific weight of the materials; screening systems; ferrous and non-ferrous metal separators; inert material processing (separation of metals, very ferrous and non-ferrous fractions as well as extraneous materials such as batteries or electronic scrap, for example). Based on your specifications, we will combine the individual units in order to achieve the best separation and sorting results for you.

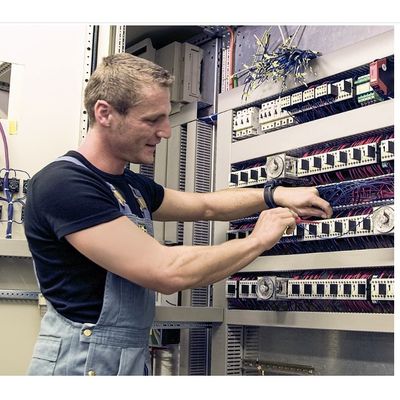

Herhof - Controlling and Switching Systems

Herhof GmbH will provide you with the entire control and feedback control system for biowaste composting and Herhof MBT plants. By means of these systems, the entire plants can be operated, monitored and controlled in fully automatic mode. In doing so, certain variables, such as temperature, CO2 content and volume flows, are constantly electronically monitored. If necessary, automatic adjustments to the set variables will be made to ensure continuous optimum conditions for the operation of the plants.

Herhof - Exhaust Air Treatment System

With implementation of the 30th BImSchV (German emission control ordinance) there are strict limits for the operation of mechanical-biological plants in Germany. The total carbon emissions in the exhaust air are not only limited in concentration, it is also limited in the loading of carbon emitted. This can be met with the LARA® system.

Herhof - Water Treatment Technology

„Treat waste water, where it is produced.“ That is the principle guiding our compact and intelligent system of process-water production waste water treatment. Developed within the Herhof group and suitable for a wide range of applications, the system is based on a high efficiency biological process combining biological purification, membrane filtration (ultrafiltration) and intermittent ventilation. All of the purified condensate produced during biodrying can be used as process water and introduced directly into the cooling system, where it is evaporated. This well-engineered recycling mechanism saves considerable amounts of fresh water.