- Home

- Companies

- Hexcel Corporation

- Products

Hexcel Corporation products

Carbon Fiber

HexTow - Continuous Carbon Fiber

HexTow carbon fiber is the preferred carbon fiber for the world’s most advanced aerospace and industrial composite applications. Carbon fiber is stiffer, stronger, and lighter than other fibers. It is selected for its high strength, lightweight, superior stiffness, electrical conductivity, low thermal expansion, high thermal conductivity and corrosion resistance.

HexTow - Chopped Carbon Fiber

Chopped carbon fiber is used in compression and injection molding compounds to produce machine parts, gears and chemical valves. The finished products have excellent corrosion, creep and fatigue resistance, plus high strength and stiffness characteristics.

Fabrics/Reinforcements - Woven Reinforcements

Hexcel - Carbon Fiber Reinforcements

Hexcel manufactures a complete line of HexForce woven carbon fabrics. The range includes traditional fabrics (3K, 6K, 12K, 24K), flat-tow 12K and heat-set-uni fabrics. Hexcel’s carbon fiber reinforcements are widely qualified by all major aircraft manufacturers - in both dry and prepreg form. These fabrics use fibers that are produced under stringently controlled conditions, extensive testing and documentation.

Hexcel - Glass Fiber Reinforcements

The versatility of glass as a fiber makes it unique industrial textile material. Woven glass fibers offer an excellent combination of properties from high strength to fire resistance at a more affordable cost. Wide ranges of yarn sizes and weave patterns provide huge number of design potential allowing the end user to choose the best combination for material performance, economics and flexibility. Hexcel produces Glass Fiber Reinforcements in a wide variety of areal weights, from 48 to 1300 gsm.

Fabrics/Reinforcements

HexForce - Bias Weave Reinforcements

Continuous rolls of carbon fiber fabric in which the warp and weft yarns are oriented on the bias at +/- 45°. Patented solution to optimize material usage: Hexcel has developed a patented process to manufacture continuous rolls of carbon fiber fabric in which the warp and weft yarns are oriented on the bias at +/- 45° in standard plain or crow foot satin weaves.

Prepregs & Resins - HexPly Prepregs

HexPly - Model M77 - Snap-Cure

HexPly® M77 is a fast-curing epoxy prepreg that enables automotive components and sports goods to be press-cured in 2 minutes at 150° C. The low tack of HexPly® M77 enables the prepreg to be cut into precise shapes by laser cutter. The individual plies can then be oriented, assembled and consolidated into a flat preform by robot. Once in the mold HexPly® M77 has an optimized gel time that allows the resin to flow into the contours to produce the precise geometries required. The high Tg of 125°C enables the cured parts can be demolded while hot for a faster production cycle.

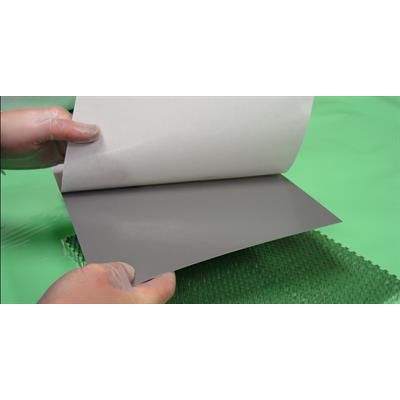

HexPly SuperFIT - Prepregs for Glass and Carbon Fiber Reinforcements

SuperFIT™ prepregs are glass and carbon fiber reinforcements that have been partially impregnated with epoxy resin. This partial impregnation leaves them with one tacky face and one dry face for easier handling. SuperFIT™ prepregs are processed by applying heat and vacuum, which activates the resin, enabling it to flow and fully infuse the reinforcement. SuperFIT™ prepregs provide a quick and cost-effective way of producing large, thick laminates.

Adhesives

HexBond - Adhesives

Hexcel manufactures a wide range of film adhesives, foaming films, primers and liquid shims for metal-to-metal and composite bonding.

Honeycomb

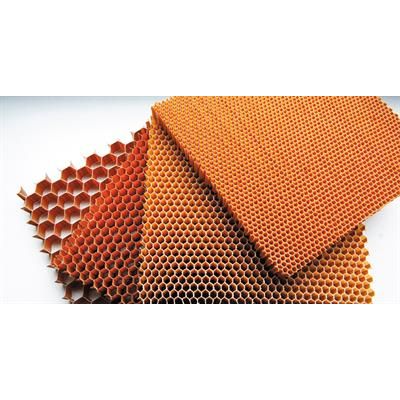

HexWeb - Honeycomb

HexWeb honeycomb provides exceptional stiffness and strength with little added weight for aerospace and industrial markets. Honeycomb is a lightweight core material which is available in a variety of cell sizes and densities, providing a wide range of mechanical and thermal properties. HexWeb® honeycomb provides a unique structure made from a variety of web materials including fiberglass, aluminum, and aramid/para-aramid mechanical papers.

HexWeb - Model EC - Engineered Core

HexWeb® engineered core (EC) encompasses a wide range of unique processing technologies used to add value to blocks or slices of HexWeb® honeycomb, also known as flat core. With advanced computer-aided design and manufacturing techniques, flat core is formed, shaped, machined and/or bonded to create high quality core details and assemblies to precise customer specifications.